Turning a Nasty Job into Icing on the Cake

The move from conventional turning to helical milling allowed this job shop to feed faster, take lighter cuts, raise the material removal rates but not cutting forces, and transform a nasty turning job into a moneymaker.

Posted: May 29, 2017

Because of their irregular dimensions and sand inclusions, stainless steel castings make it tough enough to get consistent results when machining exterior surfaces. In ID turning, matters just get worse. The main problems are chatter in long-reach boring bars leading to sudden tool rupture, chip evacuation in the bore and less-than-ideal presentation angles at the cutting edge of a concave surface. And when the tool shatters inside the bore and out of sight, the operator often can’t react soon enough to avoid a tool wreck. Bachhuber CNC Machining (Mayville, WI) faced this exact problem when opening a large bore in a cylindrical casting of austenitic stainless steel. The castings, about 18 in long and 18 in ID, came in with the usual surface inclusions plus widely inconsistent ID dimensions. The high and low spots led to unpredictable interrupted cuts during initial roughing. As a result, rough turning of a single piece to remove about 3/8 in on radius took half an hour and often demolished three tools. It also drained all the profit out of the job.

Now the same roughing job takes just eight minutes and the tools last six times longer. Finishing goes faster as well. A once-problem job now runs profitably without any price increase to the customer. How? The key to the gain is a process change to helical milling using a Power-Feed 13+ high feed mill from Ingersoll Cutting Tool Company (Rockford, IL). “It’s a completely different process that changes the game,” says Tim Majerus, a field sales engineer for Ingersoll. “The high feed cutter in the helical milling mode feeds fast and takes lighter cuts than a conventional turning setup, which reduces cutting forces and virtually eliminates the risk of catastrophic tool failure.”

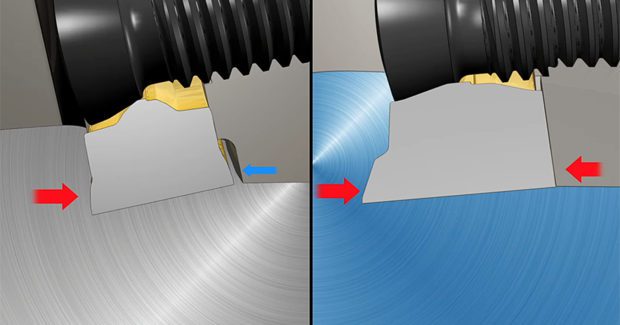

Unlike orbital milling, helical milling involves simultaneously feeding on all three axes to enlarge a hole: advance on the Z-axis while interpolating on the X- and Y-axes. The process has even successfully opened holes from the solid and become one of the most popular techniques for live-tool turning, both OD and ID. By contrast, orbital milling uses a step-and-orbit cycle and works only to enlarge open holes. Since there is very little contact area between tool and workpiece at any instant, cutting forces with both helical and orbital milling are much lower than in stick-tool turning. Completely absent is the cutting friction characteristic of conventional stick-tool rough turning. High feed geometry in the cutter simply accentuates the benefits. “The cutting forces found in helical milling are so low that they enable faster material removal on light, low-power machines,” notes Majerus.

“The tool has never shattered in the new arrangement. The insert edges simply wear gradually, giving us a secure process,” adds Dick Lain, the sales manager at Bachhuber. “Previously, conventional turning led to tool rupture regularly and damage to the boring bar occasionally. Sometimes a damaged tool dug in where the operator couldn’t see it until too late and pulled the workpiece right out of the chuck.” Operating 16/5, this 18-man contract machine shop serves a variety of industrial markets as the sister division of Bachhuber Manufacturing Corporation, an ISO 9001 manufacturer of press automation equipment. The job in question is remove about 3/8 in of material from the bore of a tubular casting made of modified 304 stainless steel. The part is a component in process piping systems, with an annual volume of 500 parts ordered in 20-piece lots every two weeks. “Basically, the job runs continuously, making it well worth optimizing,” states Lain.

At first, the tool breakage was even worse because of the sand inclusions and inconsistent dimensions in the feedstock. The foundry then hand ground the IDs to eliminate the worst high spots, which only helped somewhat. The next step was to move the roughing portion of the operation to a more rigid machine in order to reduce chatter. Results improved, but only barely. The tools lasted longer on average but still fractured unpredictably. The process was still far from secure. Then in May 2016, lead machinist Tim Pieper called Majerus for a more comprehensive solution. “They have been our ‘go to’ source for difficult machining challenges for years,” explains Pieper, “so it just made sense. As a small shop, we haven’t got the resources to seek out optimum solutions on our own.”

Majerus recommended the process change to live tool turning during his first visit, knowing it was certain to improve results. He also noticed that several machine tools on the shop floor were interpolation-programming ready. After consultations with Tom Jaggers, a milling product manager at Ingersoll headquarters, Majerus came back with the Power-Feed 13+ mill, a relative newcomer in the market, and machining parameters based on helical milling. The Power-Feed 13+ has proven out in a variety of heavy pocketing, profiling and cavity milling applications. It features extra thick inserts with extremely free-cutting top face geometries in a new secure seating arrangement. In a high feed environment, this tool can handle depths of cut up to 0.078 in.

In trials, the tools lasted longer as promised (about six times longer) and just wore down gradually, never shattering. Moreover, they cut the roughing cycle time by two-thirds. Edge life increased to two parts (vs. 1/3 of a part) and cycle time was reduced to 8.27 minutes from 28 minutes. Parameters for the trial were 400 sfm, 107 ipm and 0.060 in DOC using water soluble cutting fluid. By comparison, the previous parameters in the turning mode were 300 sfm / 3.6 ipm / 0.375 in DOC. “We were happy enough with the improved tool life and the predictability of it,” recalls Lain. “The throughput gain was icing on the cake.”

“Basically, we’re feeding faster and taking lighter cuts, which raises the material removal rates but not cutting forces,” explains Majerus. “That’s the generic beauty of high feed tooling.” Subsequently, Pieper and Majerus raised the speed to 600 sfm, leaving the feed rate and DOC unchanged. Throughput improved as a result, with no trade-off in tool life. These are now the current standard parameters at Bachhuber. “We’ve cut machining costs in half with the switch to this helical milling tool, avoiding a price increase to our customer,” says Lain. “Right now, those savings are helping us to recoup the tooling costs involved in conventional turning.”

Bachhuber Manufacturing Corporation, 450 Steel Lane, Mayville, WI 53050, 920-387-5537, www.bmchome.com.

Ingersoll Cutting Tool Company, 845 South Lyford Road, Rockford, IL 61108-2749, 815-387-6600, Fax: 815-387-6968, [email protected], www.ingersoll-imc.com.