Reduce Moisture-Absorption and Cracking Risks with Seamless Wires

Not every welding application requires the benefits that higher priced seamless wires provide. But when moisture must be controlled to help minimize the risk of hydrogen-induced cracking in demanding high-strength applications – and with it, costly repairs or potentially catastrophic weld failures – seamless welds are the ideal solution for the job.

Posted: May 22, 2017

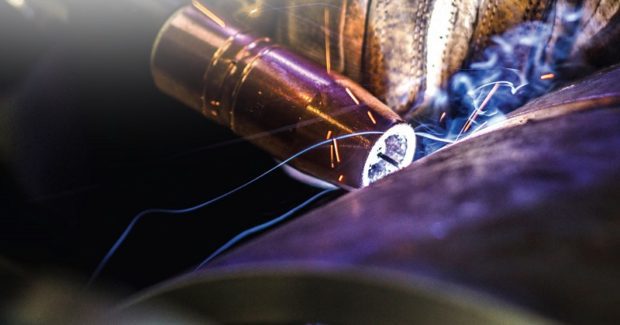

Reducing the opportunity for moisture pickup in both the filler metal and deposited weld metal is important in any welding operation, but especially in industries with more critical applications. Controlling moisture helps minimize the risk of hydrogen-induced cracking in these demanding high-strength applications, and with it costly repairs or potentially catastrophic weld failures. Seamless wires can help in moisture-control efforts. These filler metals also offer excellent impact toughness, even at lower temperatures, and low hydrogen properties to further mitigate cracking risks.

SEAMLESS WIRE BASICS

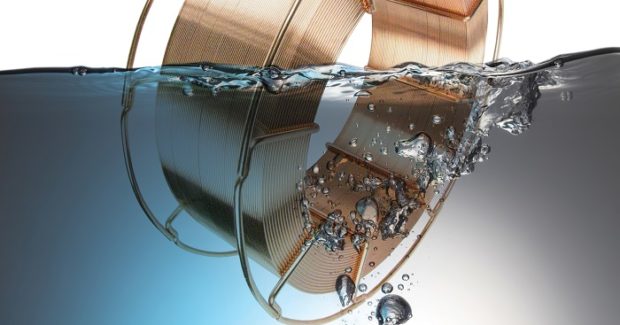

Seamless wires are available in flux-cored and metal-cored options for semi-automatic welding, as well as in submerged arc welding (SAW) cored products. As the name suggests, these wires have no seam, making them more resistant to moisture absorption, even under extreme climate conditions such as tropical temperatures and/or high humidity. The lack of seam essentially eliminates a point of moisture entry. The production of seamless wires begins with a strip of metal, typically carbon steel. The strips are folded round, then closed using high-frequency welding. They then undergo initial annealing and are drawn to the required filling diameter. Next, the tube is densely filled with flux. In several subsequent steps the wire is annealed, drawn to its final diameter, copper-coated and spooled.

This manufacturing process differs compared to producing a standard flux-cored or metal-cored wire. The result is a completely sealed wire that offers extreme resistance to moisture absorption during storage and use.

ADVANTAGES OF SEAMLESS WIRES

In addition to the ability to resist moisture, the copper coating found on seamless wire acts as another level of protection and provides optimal current transfer from contact tip to wire. This reduces contact tip wear and improves wire feedability. These properties also make seamless wires well-suited for robotic welding applications. Seamless wires have a carefully controlled cast, helix and diameter, resulting in consistent wire feeding and straight delivery at the contact tip.

SEAMLESS WIRE OPTIONS

Choosing the right seamless wire depends on the needs of your specific application. Consider the various types available:

- Seamless flux-cored wires: Standard flux-cored wires can require the addition of specific elements that scavenge out hydrogen from the weld; however, these scavengers may affect how smoothly the wires can weld. Seamless flux-cored wires do not require these additions and, as a result, provide excellent weldability. They are also available with sub-H4 hydrogen levels, or those with four milliliters of hydrogen or less per 100 grams of weldment, to further reduce the opportunity for hydrogen-induced cracking. Seamless flux-cored wires also tend to have a thin slag layer that removes easily, reducing time spent in weld cleanup. Seamless flux-cored wires are a good choice for multiple industries, but have proven especially beneficial within the oil and gas segment in offshore, pressure vessel, process pipe and spool fabrication applications. This industry segment tends to have applications in more challenging climates and can require more aggressive demands for mechanical properties and low hydrogen.

- Metal-cored: Seamless metal-cored wires are especially well-suited for applications that require high strength and superior mechanical properties, as well as those requiring fast travel speeds and good gap bridging. While these wires have not been widely adopted in North America, they do offer advantages for certain critical applications where moisture and wire feedability are concerns. Market factors, climate conditions and the critical nature of the application are all drivers that can lend themselves to choosing seamless metal-cored wires. Like seamless flux-cored wires, metal-cored options are also good for the oil and gas industry, as well as heavy equipment applications, especially those requiring more stringent mechanical properties (e.g. higher tensile/yield strength and/or low temperature toughness).

- Submerged arc seamless wires: Seamless wires for SAW are a composite type electrode. Seamless SAW wires are typically used in extremely high-strength applications, such as those in the offshore industry. Seamless wires for submerged arc applications offer superior mechanical properties over solid wire products because they can be alloyed within the core to provide specific properties in the weld.

AN OPTION FOR HIGH-STRENGTH APPLICATIONS

Not every welding application requires the benefits that seamless wires provide. And because seamless wires typically have a higher purchase cost, there is less need to consider them in applications where there is a low risk of hydrogen-induced cracking, or where low hydrogen properties and high strength aren’t needed. However, in high-strength applications where ensuring low hydrogen levels and resistance of moisture absorption are critical, seamless wires are a good option to address these issues. Choosing seamless wires can help welding operations meet the specific needs of demanding welding applications and reduce potentially costly rework.