Metal 3D Printing for Land, Sea, Air and Space

When a submarine manufacturer saved significant time and cost by using Electron Beam Additive Manufacturing to 3D print a titanium Variable Ballast tank, the technology became the only industrial-scale metal 3D printing process with approved parts for land, sea, air, and space applications.

Posted: May 22, 2017

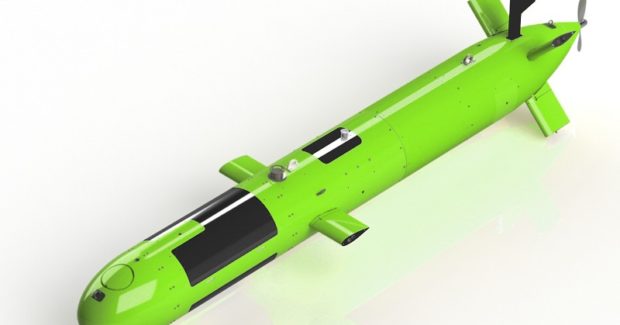

International Submarine Engineering, Ltd. (ISE; Port Coquitlam, BC) and International Submarine Engineering Research (ISER) are world leaders in the design and integration of underwater vehicle systems that include AUVs, ROVs, and HOVs. ISE also manufactures assorted terrestrial robotic systems. Since 1974, these two companies have developed unique capabilities for turning diverse conceptual requirements into functional solutions for a broad customer base. To meet individual customer needs, ISE/ISER, which are ISO 9001 certified, utilize a multidisciplinary engineering approach to provide integrated solutions that meet operationally and functionally complex programs.

The titanium Variable Ballast (VB) tank is a sub-system of ISE’s Arctic Explorer Autonomous Underwater Vehicle (AUV) class of vehicles. They previously built two Arctic Explorers for Natural Resources Canada/Defence Research and Development Canada (DRDC) to map the sea floor underneath the Arctic ice shelf in support of Canada’s claim under Article 76 of the United Nations Convention on the Law of the Sea. The Arctic Explorer is the largest of the Explorer AUV class, measuring over seven meters (nearly 23 ft) long and weighing over 2,000 kg (4,409 lb). It can be launched from a ship or through an ice-hole, and its modular sections can be separated for transportation. Its unique VB system enables the vehicle to park on the sea floor or hold itself on the underside of the ice during missions. Rated to 5,000 meters (roughly 3.11 miles) depth, the Arctic Explorer is designed to remain underwater between missions for extended periods of time. A small Remotely Operated Vehicle (ROV) conducts all servicing and charging after the AUV is attached to a docking head.

After the closure of their former supplier of VB tanks, an overseas titanium forging facility that produced propellant tanks for the Russian space program, ISE did not want to risk further delays in their exploration plans so they approached Sciaky, Inc. (Chicago, IL), a subsidiary of Phillips Service Industries, Inc. (PSI; Plymouth, MI ) and provider of metal 3D printing systems. They reached out after learning that Sciaky had 3D printed titanium propellant tanks for Lockheed Martin Space Systems in 2015. The engineers and project management team at Sciaky immediately put together an aggressive plan to produce a new titanium VB tank for ISE using their patented Electron Beam Additive Manufacturing (EBAM™) 3D printing process. In the end, this technology helped ISE reduce production time from 16 weeks to 8 weeks, as well as reduce overall costs as compared to retooling with a new forging supplier.

In addition, the VB tank created with the EBAM process passed the same vigorous qualification testing as the tank previously created with the forging process. ISE now has plans to 3D print other critical titanium parts with the EBAM process. The VB tank that was 3D printed using the EBAM process will be installed onboard a new Arctic Explorer AUV for the University of Tasmania. This new Explorer AUV will be deployed in Antarctica after extensive trials and training operations. “We are proud to help them cut production time by 50 percent and reduce costs by 3D printing their titanium VB tank with this unique process,” said Bob Phillips, the vice president of marketing for Sciaky. “EBAM technology is the world’s only industrial-scale metal 3D printing system with approved parts for land, sea, air, and space applications.”

As the most widely scalable metal 3D printing systems in the industry in terms of work envelope, EBAM technology can produce parts ranging from 8 in (203 mm) to 19 ft (5.79 m) in length. It is also the fastest deposition process in the metal additive manufacturing market, with gross deposition rates ranging from seven to 20 lb (3.18 kg to 9.07 kg) of metal per hour. The process brings quality and control together with IRISS™ – the Interlayer Real-time Imaging and Sensing System that is the only real-time monitoring and control system in the metal 3D printing market that can sense and digitally self-adjust metal deposition with precision and repeatability. This innovative closed-loop control is the primary reason that the EBAM 3D printing process delivers consistent part geometry, mechanical properties, microstructure, and metal chemistry from the first part to the last.