Improving Lead Time and Reducing Costs at Norwood

To meet market demand for faster delivery of larger and stiffer rotor shafts, the huge WFL M80 mill-turn at Siemens Norwood has a turning, boring and milling unit arm that can perform 20 distinct CNC operations across five axes.

Posted: May 31, 2017

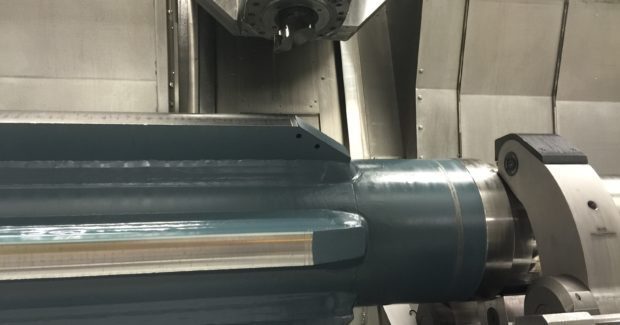

The Siemens Large Drives motor factory in Norwood, OH, recently made an investment to upgrade their manufacturing capabilities in the 117-year-old facility with a new and highly advanced machine tool that will aid in manufacturing steel rotor shafts that are eventually used in Above NEMA electric motors. Their new WFL M80 mill-turn is 52 ft long, weighs 58 tons and contains a 72-tool magazine that automatically connects and calibrates to the turning, boring and milling (TBM) unit. This machine is controlled by a Siemens Sinumerik 840D controller and HMI. In turn, the Siemens Norwood plant can now provide a new product to fill a major gap in the market and fulfill customer needs. The key advantage of this new machine is its ability to save time and utilize less manpower.

When shafts arrive in the facility as raw material, several modifications, including full-penetration welding, must be made before they can withstand the extreme torques inside a motor. The welding procedure for full-penetration welds requires three or four weeks of time-intensive, internal and external labor and quality checking. Almost all shafts require turning, milling, drilling and tapping procedures that were historically performed on separate machines. The transitioning between those multiple machines immediately adds setup time, creates transportation waste and increases risk of scheduling conflicts.

In addition to those concerns, many of Norwood’s existing machines are over 30 years old, which typically leads to increased maintenance over the lifetime. With the new WFL M80 mill-turn, all of those procedures can be performed sequentially in a faster time and with less supervision, also eliminating former waste and potential risks. The new process coined as “fluting” is subtractive manufacturing that mills out material from a larger starting radius versus the previous additive manufacturing that welds more material from a smaller radius. This process takes less than one day versus several weeks in the previous process.

The need for the WFL M80 follows a recent market change that has required larger frame sizes, higher speeds and, thus, larger and stiffer rotor shafts. Traditionally, the volume for larger rotor shafts – the size which is best suited to run on this new machine – has been low, but increased customer use of variable frequency drives has shifted the industrial motor business to invest in new manufacturing technology. A capital investment team at Norwood discovered a profitable estimation to acquire this new mill-turn and launched their research on three different mill-turn machines during the winter of 2013. The WFL M80 mill-turn was selected as the best investment during the spring of 2014 by using a complex decision matrix of both core needs and auxiliary functions. The transportation of the mill-turn, the installation into the shop and the training by the designers occurred over months, finishing in the fall of 2015.

The sheer size of the WFL M80 is impressive, not to mention its vast capability, 20 different machining operations and precise, high speed tooling. Overall, the WFL M80 mill-turn is 16 ft wide, 13 ft tall and 52 ft long, weighing in at 58 tons. In fact, the machine is so large that it could not fit through the existing door to the facility, so part of the garage frame had to be removed and then replaced once the machine was inside. The new CNC machine utilizes 72 unique tool heads, each of which is automatically selected and calibrated by the internal tool measuring system and software. The CNC controller on the machine is a Siemens Sinumerik 840D as well. The mill-turn does more in less time: it removes 60 percent more material with each pass than the previous machine.

In addition, the length of the capable shafts for CNC milling has increased to 220 in over the previous machine’s 117 in maximum limit. The turning, boring and milling (TBM) unit arm can perform 20 distinct CNC operations across five axes. All of these aspects make the new mill-turn a highly valued asset to Norwood’s rotor manufacturing process.

With great technologies also comes great challenges: the Norwood team was faced with learning a WFL proprietary coding language to operate the new machine, requiring intensive training to overcome a steep learning curve. Not only is the programming new to Norwood, but the logistics of installation and the release to production demanded constant cross-functional teamwork. There were several weeks of preparation and manual labor to finish the installation, followed by machine calibration and training that had to take place before the first production part was created and released.

With the successful installation of the new machine, Norwood aims to significantly improve their lead time and reduce manufacturing costs, as well as learn valuable experience for other manufacturing equipment coming to this facility in the future.

Siemens Industry, Inc., 4620 Forest Avenue, Cincinnati, OH 45212, 513-841-3100, www.industry.usa.siemens.com.