High Speed Plasma Cutting System Slashes Operating Costs

The Hypertherm XPR300 plasma cutting system on the PlasMAX high speed cutting machine from Controlled Automation increases cut speed, dramatically improves productivity, triples realized consumable life in many applications, and slashes operating costs by over 50 percent.

Posted: May 29, 2017

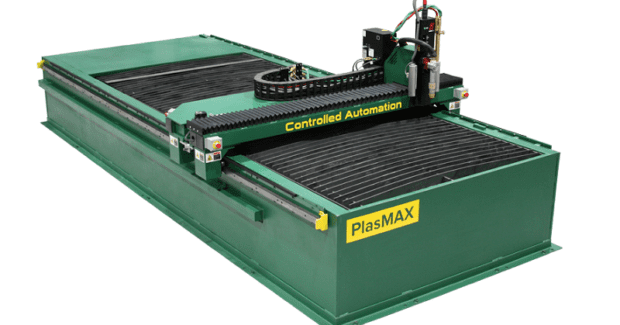

Controlled Automation, Inc. (Bauxite, AR) introduces the new XPR300TM plasma cutting system from Hypertherm, Inc. (Hanover, NH) for all of their plate processing machines, including their PlasMAX high speed cutting machine. XPR300 represents one of the most significant advances in mechanized plasma cutting technology ever. Expanding on the foundational HyDefinition process with new technologies such as Cool Nozzle, Vented Water Injection (VWI), vent-to-shield, plasma dampening and advanced arc stability, this plasma cutting systems achieves a new level of cut quality, X-DefinitionTM. In addition to unmatched cut quality on mild steel, stainless steel and aluminum, the XPR300 also increases cut speed, dramatically improves productivity, triples realized consumable life in many applications, and slashes operating costs by over 50 percent.

The unitized PlasMAX high speed plasma cutting machine differs from any other plate cutting system with its unique all-aluminum gantry design for the highest speed accelerations between parts. This allows the machine to produce the most critically accurate plasma cut parts possible for material up to 4 in (102 mm) thick and with maximum material sizes up to 8 ft (2.5 m) wide to 30 ft (9.2 m) long. Its high precision linear rail is made from hardened steel that is round instead of flat to ensure little debris reside on the path of linear motion. This allows for smoother travel and less build-up of mill scale, dust and particles that can affect cut quality at high accelerated travel speeds.

This system offers the cutting edge (no pun intended) in advanced shape nesting software and beyond: its Nesting software is used for easy navigation between machines for the operator, with seamless integration with a variety of communication tools unavailable on any other cutting machine in the world. Controlled Automation imports from all current 3D drafting models (such as Design Data SDS-2 and Tekla detailing software) and communicates with the latest inventory management software (such as FabTrol and FabSuite) to handle the cutting edge of production. The advanced dual-side AC servo drive system on this machine can be controlled to accuracies unable to be matched by single-side drive systems. Dual drives eliminate the high point loading on the guide rails generated by single side drive machines under acceleration, which lead to guide failure. The dual drive system on either end of the traveling gantry provides machine accuracies to ± 0.15 mm/m (0.006 in/36 in).

Controlled Automation, Inc., 15701 West Sardis Road, Bauxite, AR 72011, 501-557-5109, www.controlledautomation.com.