How to Drive Improvement in Your Existing Welding Power Source Fleet

Utilizing external weld monitors that work with any brand of machine and any welding process can help drive productivity and efficiency gains, improve quality, and help reduce costs and lost time. Here are some ways for your shop to generate greater profitability through better information management.

Posted: May 27, 2017

In increasingly competitive markets, many metal fabricators are looking for ways to improve productivity, maintain quality and generate greater profitability. Utilizing advanced welding information management systems is one solution that companies can turn to in order to meet these goals. An integrated system is typically the ideal choice, but a shop might not be in position to upgrade or replace their welding power source fleet. In this situation, there is another way: utilizing external weld monitoring systems that are deployable on any brand of welding power source (old or new) in both manual and automated welding applications. These allow shops to leverage their existing fleet of equipment while providing an information source to improve productivity and quality and significantly impact their bottom line.

BENEFITS OF GATHERING WELDING INFORMATION

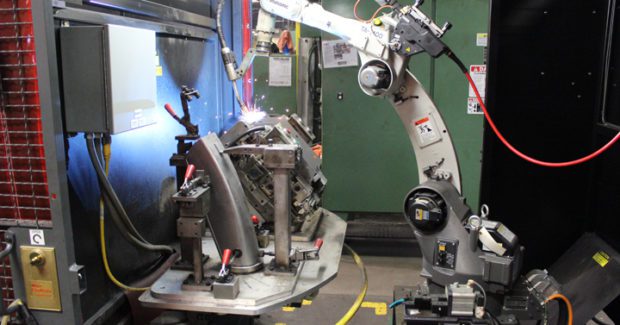

Why is it important to gather all this information? The consequences of errors such as missed or defective welds can be high, especially if the problem is not detected before a part flows through final assembly. Errors impact part quality and overall productivity because they can result in expensive and time-consuming rework. Higher levels of welding information management can help shops identify and rectify problems very early in the production welding process. These systems operate in both manual and automated welding applications. In manual operations, they provide governance over almost any factor in the welding operation: before, during and after the actual welding process. In automated welding, problems are reduced through process control and weld process quality measurement.

Some of the benefits realized through the implementation of these systems in a manual welding operation are:

- Improve and expedite welding operator training, resulting in reduced errors and lower costs.

- Prevent and detect missing welds.

- Identify over-welding and under-welding.

- Measure overall equipment effectiveness (OEE) and track additional productivity metrics.

- Manage work flow.

Benefits specific to automated welding include:

- Prevent and detect missing welds.

- Identify incomplete welds.

- Identify out of process welds.

- Identify weld defects with enumeration of detractor.

- Measure OEE and additional productivity metrics.

These systems can also help shops implement more effective predictive and preventive maintenance, because actions are based on empirical data. Primary welding parameters can be monitored in real-time with alerts provided when action is needed. Another benefit of this level of welding information management is traceability and verification that correct welding procedures are followed, creating a digital record of every weld for every part produced.

A RANGE OF SYSTEMS TO MEET VARYING NEEDS

There are a range of external weld monitoring systems that can connect universally to different brands of welding power sources, allowing operations to reap the benefits of higher level information with their existing power source fleet. The resulting data provided by these systems is unified, giving operations a single presentation framework even when the information is captured from different types of welding stations. Choosing the right system for an application depends on several factors, including whether the welding process is manual or automated, if it needs to be integrated with the computer network, and how much data a company is looking to collect about their welding process. Upon assessing these factors, the shop will have various options to consider.

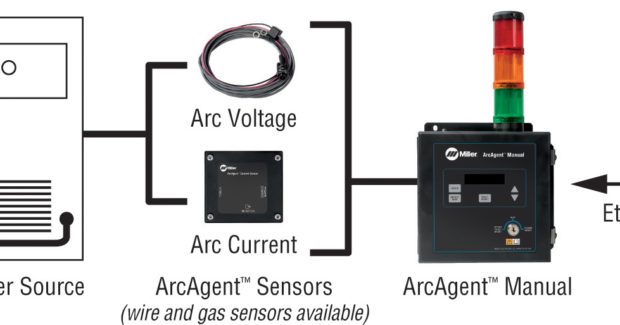

For example, one external monitor can be used to connect manual or robotic welding systems to an advanced welding information management system. The connection of this external module provides basic productivity information, such as total weld count and total arc time. Another system that is specific to manual welding applications offers digital cell integration. Connecting that external module to a PC running a human-machine interface (HMI), multimedia content governs the welding and non-welding steps to ensure proper part production and best practices are followed. This provides missing weld detection and prevention, weld sequence governance and total control of the welding and fabrication processes.

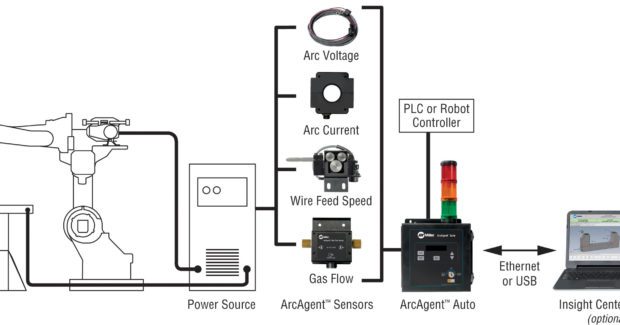

There are more sophisticated systems designed to be used in fixed automation or flexible robotic applications that provide the same capabilities of a manual welding system but are designed to be integrated with control equipment, such as PLCs and robot controllers. The primary benefit of these options is process control and weld fault detection, and they allow shops to monitor current, voltage, wire feed speed, weld duration and gas flow, among other factors. There are also systems that offer advanced features in a portable package, which is a good option for welding technicians or engineers who may need a tool they can take from location to location for audits, assessments and productivity trials.

Companies should be aware that there are some additional steps that must be taken to realize the benefits of adding an external weld monitoring solution. For example, sensor connections are required for voltage, current, gas flow and wire feed, so look for a system that uses universal sensors across solutions. Also, manual applications require an external mechanism to interrupt welding power source operation when the welding procedure or sequence has been violated.

TIPS TO ENSURE SUCCESS

Successful implementation of these systems on any type or brand of power source requires more than just purchasing them. How the system is deployed is a key part of success. These systems are interactive by providing feedback, and that feedback requires a response or action on the part of the company. Weld data is only relevant and useful for driving continuous improvements when it is acted upon. It’s critical to have the proper personnel in place to help spearhead implementation and use of the system. Appointing a technical champion with knowledge in the use and benefits of the technology is essential. This person can collect and aggregate the data provided by the system, and act as a liaison between top management and welding operators. Because operators play such a vital role in the day-to-day welding process, securing their participation and buy-in is key.

In addition, it helps to have someone with the welding expertise and knowledge who can analyze the data and help decide how it should be used to make improvements. Ensuring that actions are actually taken based upon the data also helps build buy-in and support for the system on the shop floor. Demonstrating the return on investment (ROI) to multiple areas of the organization, from engineering to production to management, helps drive support and buy-in across the board. Utilizing external weld monitoring systems that work with any brand of machine and any welding process can help drive productivity and efficiency gains and quality improvements, while also helping to reduce costs and lost time. An effective equipment supplier is one that offers welding information solutions with new and existing equipment.