Laser Welding: How to Reduce Production Costs Before You Even Begin

Knowing how to utilize the increased flexibility gained through laser welding can enable a fabrication shop to tackle tough challenges and creatively solve them.

Posted: April 18, 2017

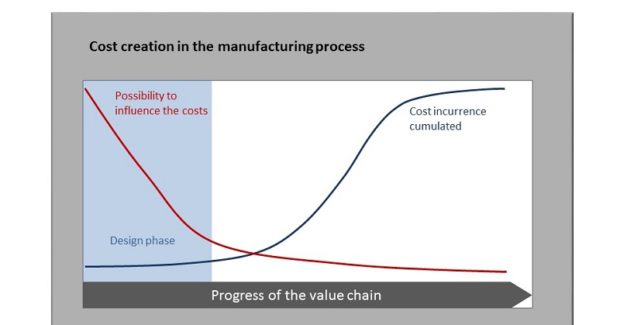

Although welding is usually one of the final processing steps in production, it has a significant impact on the entire value chain. The part design in particular is influenced by on the chosen seam geometries and where they are placed. This ultimately impacts factors such as the material utilization during the cutting process, tolerances of the formed parts, and the number of individual parts that make up the final component. Up to 70 percent of manufacturing costs are defined during the construction phase, and these costs are rarely influenced later on in the process. By design, laser welding enables fabricators to significantly reduce the cost of manufacturing a part from the very beginning of the value chain. This factor is relatively unknown, so let’s illustrate the potential money-saving designs that are enabled by laser welding.

CONVENTIONAL VS. LASER WELDING

Before diving into part design, it is important to note a few key characteristics that differentiate laser welding from conventional welding processes. In MAG welding, one of the most common conventional welding processes, an electrode introduces energy – and a lot of heat – into the component. With laser welding, a different strategy is taken. Feed rates are much higher (up to 130 ipm) and the energy focus diameter is far smaller (400 μm) on the surface of the workpiece. These factors enable fabricators to avoid distortion and rework while benefiting from high reproducibility, consistent processing times, water tight seams and high-quality results in mild steel, stainless steel and aluminum. All of this can greatly reduce the manufacturing costs per part.

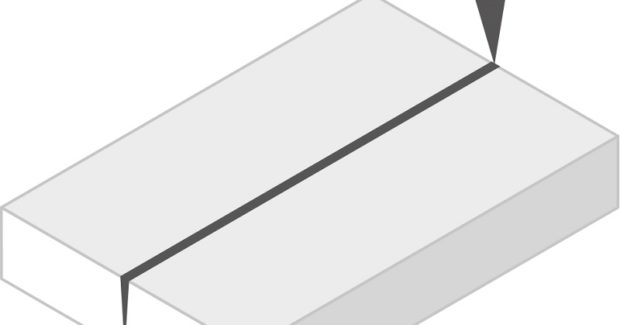

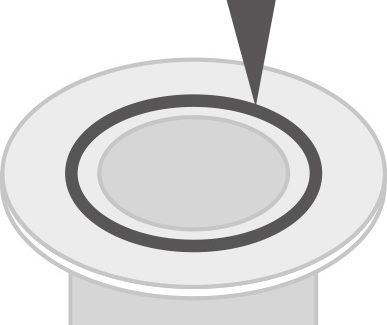

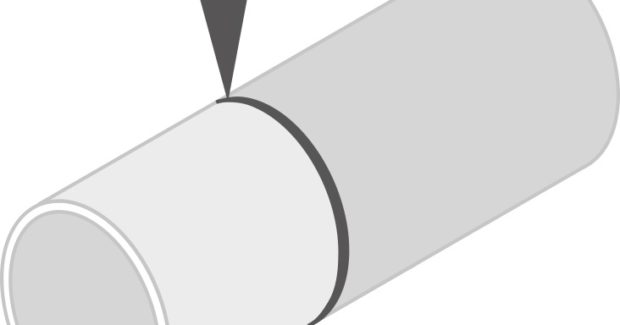

Unlike MAG welding, which is mainly limited to butt joints and fillet welds, laser welding also offers significantly greater flexibility in seam geometries. This is because the focus position can be adjusted. By varying the intensity at the surface, the depth of the weld seam also changes. The laser thus allows for deep welding that can achieve very thin seam geometries (up to 12 mm deep). However, low tolerances and minimal gaps are required for laser welding, and these two factors influence the ideal part design. Components can be designed with more individual parts and fewer bends. This reduces bending tolerances and creates long welding seams which are beneficial to fabricators due to the high feed rate of laser welding.

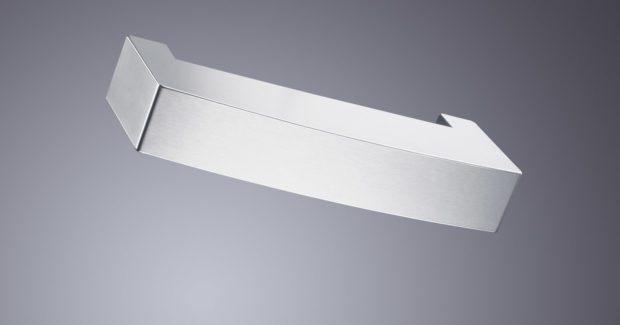

SAMPLE 1: LIGHTWEIGHT CONSTRUCTION

When transitioning from conventional to laser welding, the first consideration should be whether an adjustment to the part design will reduce the cost of manufacturing. One application where laser welding offers significant advantages is in the lightweight construction of a large but mobile component, for example, of the motion unit that moves the processing head of a 2D laser cutting machine. High speed cutting is achieved to a certain extent by the high acceleration rates of the motion unit. It is therefore advantageous to reduce the weight of these units while still achieving the same stiffness.

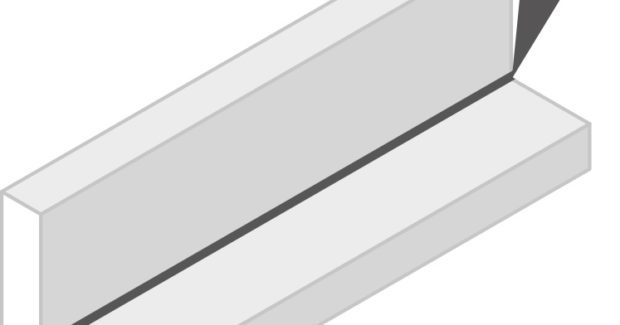

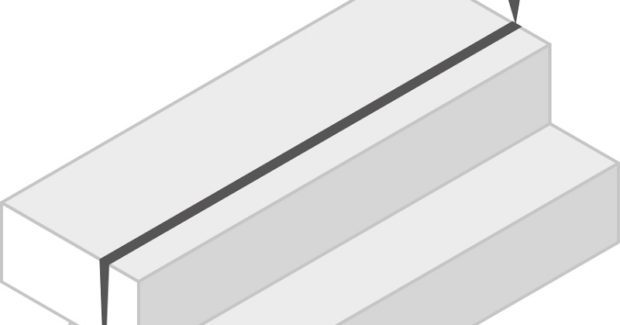

Two advantages of laser welding can be applied – both of which are not possible with conventional welding. One is the ability to join two workpieces with different sheet thicknesses. The second is the flexibility to weld T-joints from the outside of the joint without overlapping flanges. This is made possible by the low heat input, as well as the very narrow and deep seam geometry. In this example, the design engineers were able to increase the resistance torque by displacing the mass as far as possible to the outside, replacing all transverse struts with two longitudinal struts and reducing the wall thickness. This new design reduced the overall weight by 220 lb (100 kg) and doubled the possible acceleration. An annealing process is no longer required before welding due to lower heat distortion of the process and the entire component can be welded from the outside. These design changes not only significantly reduced production costs, but also the operating costs of the laser machine.

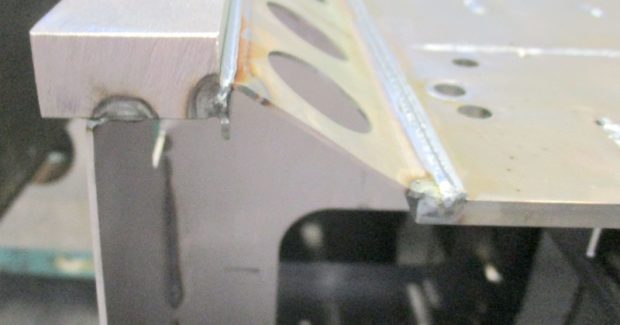

SAMPLE 2: REPLACING MACHINED COMPONENTS

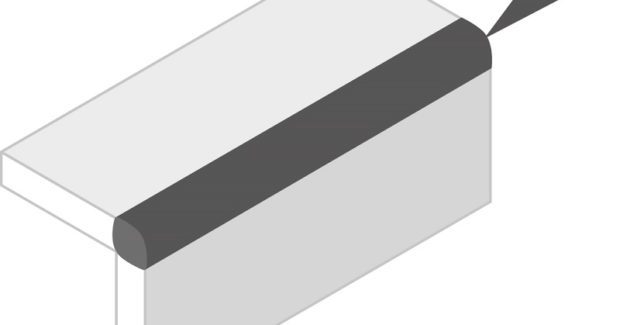

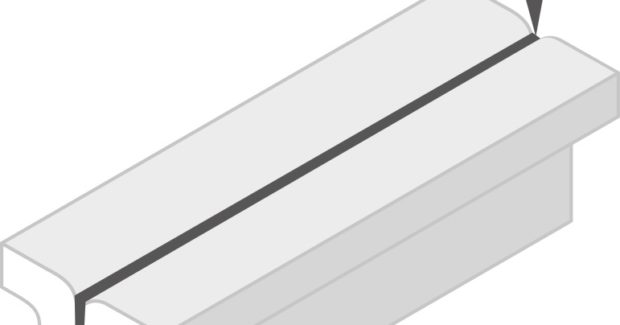

A second example of how a design change enabled by laser welding can reduce production costs involves a switch frame that was initially machined from a larger block of material in a very time-consuming and expensive process. Laser welding enables a better solution by placing two laser-cut sheets on top of each other and welding them together laterally. With this new process, the very high demands on the flatness tolerance (± 0.3 mm) is maintained, but the processing time is reduced by 90 percent and the material consumption is also dramatically reduced. The functionality has remained unchanged, but the redesign reduced costs by 80 percent.

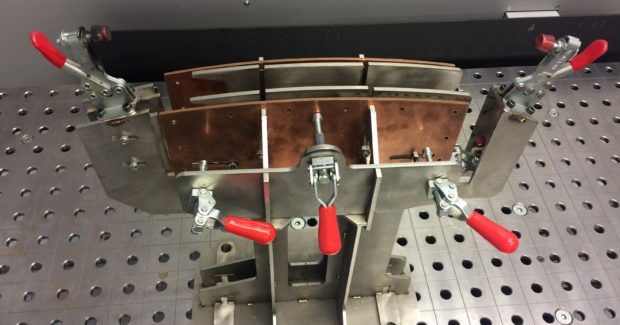

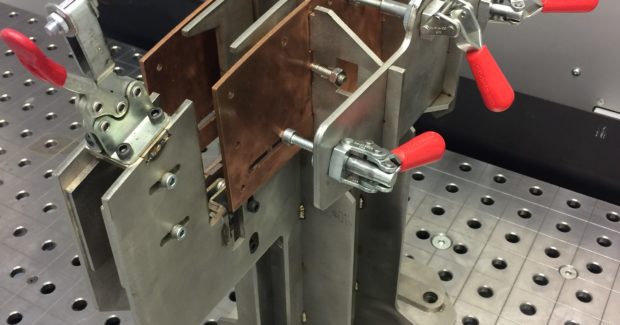

SAMPLE 3: FIXTURE DESIGN

A fixture’s job extends past securing the components for accurate processing. It also helps to cool the material, for example, through copper plates used as a heat sink, channel the shielding gas and ensure productivity through reliable, yet simple, loading and unloading. Depending on accuracy requirements and number of pieces, there are different clamping strategies that range from modular systems typically used for prototypes and small batch sizes to a fixed core of interlocked sheet metal used for processing higher volumes, to pressure devices that apply a clamping force from the outside. Hydraulic clamping systems that can be clamped from all sides at the push of a button are typically used for very large quantities and may even feature an adjustable inner core.

In this final example, the fixture design used in laser welding significantly reduced manufacturing costs by preventing discoloration and distortion, which in turn prevented rework while accelerating the process. Its fixed core design featured two copper plates which served as a heat sink. Three sides were held in place by pressure elements, while the forth side was blocked by a stop. In addition, by designing the fixture with a rise the fabricator improved accessibility, gained the ability to weld from below, and was able to finish the entire processing step with a single fixture.

By redesigning sheet metal parts and creating a proper fixture to take full advantage of the increased functionality of laser welding, many costs can be saved in fabrication shops, both large and small. These redesigns take place at the beginning of the value chain and play a large role in each step that follows. They give manufacturers the ability to construct these components quickly, without sacrificing strength. They also open the door to new creative possibilities for the designer. Knowing how to utilize all of this increased flexibility can enable a fabrication shop to tackle tough challenges and creatively solve them.