High Performance Strategies for 2.5D Through 5-Axis Milling, Drilling, Mill-Turn and Specialty Applications

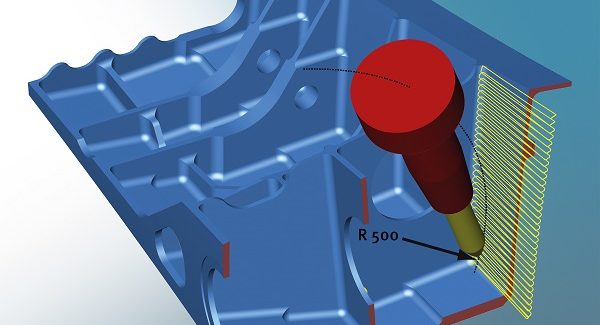

hyperMILL MAXX Machining CAM software from OPEN MIND Technologies applies conical barrel cutters to large planar, ruled or general surfaces for finishing; five-axis roughing for engine casings and radial components; and drilling with 5-axis helical motion using standard endmills to open pockets with good chip removal.

Posted: April 21, 2017

In Booth 5240, OPEN MIND Technologies USA, Inc. (Needham, MA) will present their hyperMILL® MAXX Machining CAM software, a set of high performance strategies for roughing, finishing and drilling that covers 2.5D through 5-axis milling and drilling, mill-turn, and specialty applications. Finishing is a unique highlight that applies conical barrel cutters to large surfaces – planar, ruled or general. The large radius on the barrel allows large step-over, while the conical surface enables short cutters to be used. Holders are assured with collision detection process. The system also allows user to control the contact point to increase cutter life or to help reach in specific regions. Roughing is based on the Volumill™ toolkit and has been applied to 2.5D pocketing, 3D roughing, and 5-axis roughing. Five-axis roughing is well-suited to engine casings and radial components, such as in tire mold segments. Drilling uses 5-axis helical motion to open pockets with good chip removal by using standard endmills.

With application in 2.5D, 3D, and 5-axis milling, and millTURN, hyperMILL CAM software is available standalone with hyperCAD®-S CAD for CAM, or integrated in SolidWorks or Autodesk Inventor. OPEN MIND provides high value solutions, dedicated CNC postprocessors, and innovative approaches, such as in-process probing for alignment and measurement.

OPEN MIND Technologies USA, Inc., 1492 Highland Avenue #3, Needham, MA 02492, 888-516-1232, www.openmind-tech.com.