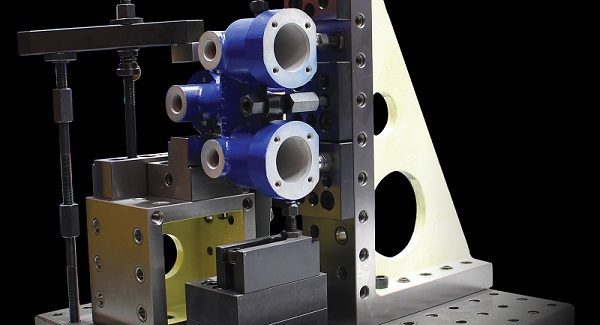

Flexible Tooling System for Quick, Accurate Low Volume Machining

The 5016 Modular Fixturing System from Bluco can be used in both vertical and horizontal machining centers, and the baseplates are customized to fit the dimensions of each specific CNC machine tool.

Posted: April 19, 2017

In Booth 5677, Bluco Corporation (Aurora, IL) features their 5016 Modular Fixturing System that combines a proprietary baseplate design and over 250 proprietary tooling components to deliver a flexible tooling system that enables companies to quickly and accurately hold low volume pieces for machining. The baseplates come standard with a pattern of alternating 16 mm hardened bushings (±0.0004 in between centers) and M16 tapped holes, along with alpha-numeric engraving to help identify hole location. These exceedingly tight tolerances give users confidence that fixtures built on the system are right the first time and can be rebuilt a week, month or year later with the same accuracy. A typical modular fixture can be designed, built and ready to run the first piece in under an hour, compared to dedicated fixtures than can take days or weeks to be completed.

The system can be used in both vertical and horizontal machining centers, and the baseplates are customized to fit the dimensions of each specific CNC machine. For horizontal applications, larger blocks and knees are available, or baseplates can be mounted to new or existing tombstones. To achieve even more efficiency from the system, quick release mounts can be added for rapid change over between jobs. The machine operator can work on setting up the next job on an optional secondary baseplate while the current job is running.

Bluco Corporation, 3500 Thayer Court, Aurora, IL 60504-3108, 630-637-1820, www.bluco.com.