Flexible Automated Material Handling for Unmanned Production

For CNC machine tools, the Flexible Pallet Container pallet handling system from Fastems enables operators to set up new pallets while parts on other pallets are being completed, eliminating the need to stop machining to change setups.

Posted: April 3, 2017

Factory automation supplier Fastems, LLC (West Chester, OH) is celebrating production of their 500th Flexible Pallet Container (FPC) pallet handling system for CNC machine tools. The FPC is a compact, flexible automated material handling system that is housed in a single shipping-container-sized unit and arrives at the user’s facility factory-tested and ready to install. This system enables operators to set up pallets while workpieces on other pallets are being completed, eliminating the need to stop machining to change setups. It facilitates processing a large variety of product mix and small batches of parts and can also expedite high volume production.

An FPC unit has two levels served by a stacker crane and requires a fraction of the floor space needed for a traditional pallet pool. Manufacturers can easily relocate containers in response to changes in production strategies and factory layout. One stacker crane services up to two machine tools and two loading stations. Adding a third container permits automation of an additional machine tool and increases the number of pallet spaces available, expanding opportunities for unmanned production. Five different models of the FPC system handle loads from 750 kg (1,650 lb) to 7,500 kg (16,500 lb). The open, independent MMS control (manufacturing management system) guides and monitors FPC operation and seamlessly interfaces with ERP systems and CNC programs generated by CAM software. MMS control technology easily adjusts to changing production needs and provides multiple scheduling strategies. Options for full or partial operator participation permit seamless insertion of rush jobs followed by full resumption of previously scheduled production. The FPC system features an intuitive user interface and an ergonomic design that safeguards workers.

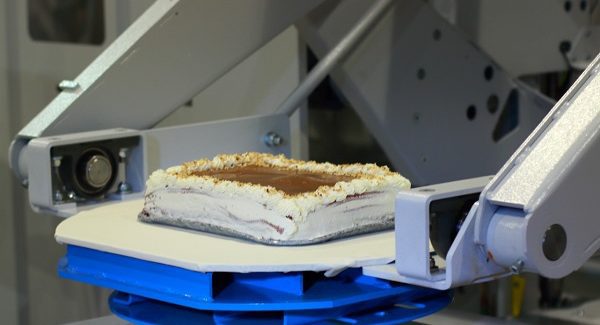

Established in 2006 as an independent integrator of flexible automation systems, Fastems, LLC is a wholly-owned subsidiary of Fastems Oy Ab (Tampere, Finland), which currently employs about 350 people in the U.S., Europe, and Asia and has more than 4,000 systems installed worldwide. They introduced their first FPC system in 2001 and recently recognized the 500-unit manufacturing landmark with an event at their Tampere factory, where the 500th system’s stacker crane delivered a celebratory cake. “We have manufactured these containers for 16 years and now it is time for this 500th container to be shipped to China,” said Markku Bollmann, the vice president sales and marketing at Fastems Oy AB. According to Bollmann, they have delivered FPC systems to four continents worldwide.

Fastems, LLC, 9850 Windisch Road, West Chester, OH 45069, 513-779-4614, Fax: 513-779-4638, www.fastems.com.