Cutting Tool Reconditioning, Industrial Vending, Tool Boxes and Foam Inserts

Along with providing AutoCrib tool crib management software and industrial vending systems, US Tool also reconditions dull, dirty drills and cutting tools and returns them to users sized and packaged with bar-coded labels in reusable boxes, cleaned, sharpened and ready to perform like new.

Posted: April 21, 2017

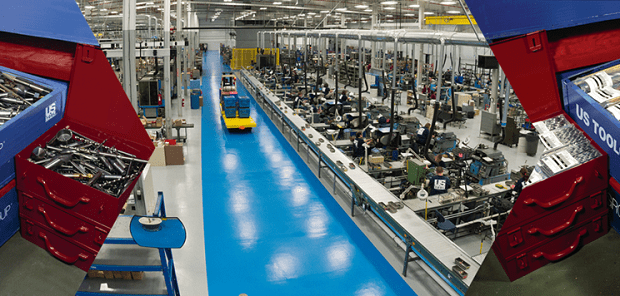

In Booth 5467, US Tool Group (Farmington, MO) explains how they recondition more than a half million drills and other cutting tools each week. This high volume allows them to amortize setup, operator training and specialized equipment costs, producing savings that are passed on to users. Their unique process is what makes them the largest cutting tool reconditioning company in North America, with capabilities that include:

- Sort, chemically clean and prepare user cutting tools for reconditioning to their specifications or industry standards.

- Reconditioning of drills, reamers, end mills, taps and most other types of high speed, cobalt and carbide rotary cutting tools.

- CNC regrinding and manufacturing of end mills and other high performance carbide tools utilizing over 36 Walter, ANCA and other CNC grinders.

- Manufacturing of special tooling for the aerospace industry featuring threaded shank and quick change adapter products.

- Simple modification of cutting tools (adding a radius, step, tang, etc.).

- Major modification of tools (changing diameter or other critical geometries).

Shops can start this reconditioning service by contacting customer service at US Tool, which will send them an appropriately sized box for their dull, dirty drills and cutting tools. They simply toss them into the box and US Tool will return the tools, sized and packaged with bar-coded labels in reusable boxes – cleaned, sharpened and ready to perform like new. US Tool is also “Premier” distributor of AutoCrib tool crib management software and industrial vending systems, and is the largest AutoCrib solutions provider in the industrial market. AutoCrib offers a variety of dispensing machines and lockers in different configurations to meet a wide range of user requirements. In addition to the operation of tool dispensing machines, the AutoCrib tool crib management software performs as a stand-alone, full-featured program to manage the traditional tool crib in a cost effective environment.

https://youtu.be/ohwd_UEfWXY

US Tool supports the AutoCrib software and industrial vending systems with their own staff of highly trained software programmers and hardware support personnel, resulting in a unique ability to provide a complete turnkey solution for these systems. The big advantages of industrial vending include:

- Reduce 20 percent to 50 percent of your inventory spend.

- Automate ordering, receiving, stocking and maintaining inventory.

- 24-7 availability with accountability for employee transactions.

- 100 percent inventory visibility: reduce stock-outs and obsolete inventory.

- Significantly reduce consumption, hoarding and theft.

- Control employee and department spending.

- Turn your inventory data into actionable information.

- Improve job costing, inventory forecasting, and demand planning.

- Reduce travel-time and other non-value added activities.

- Access control by item, department, employee, job, machine, etc.

- Increase use of re-grinds and reconditioned items.

- Reclaim floor space.

- Manage gauge calibration.

- Lot control and FOD control.

US Tool also supplies turnkey team toolbox programs, including in-house laser etched tools, foam cut drawers and user-prescribed drawer layouts. They have the capability to create full Shadow Boards for user tool boxes or interchangeable foam inserts that allow easy movement of tools from one box to another. US Tool represents most major hand/power tool manufacturers and most toolbox suppliers. This flexibility allows them to offer a solution that is tailored to user-specific brand requirements for tools and boxes, rather than being limited to a single brand. US Tool provides in-house laser tool etching for cutting tools, hand tools and other products that require professional and permanent marking identifying customer part numbers and specifications.

They also provide a portable solution for tools currently used in production. They will photograph tools at the user’s facility without disrupting work flow and create foam inserts with this information. Using shadow boards to organize their tool boxes will help users remove the cost of overstocked items, as well as give them a quick visual of tooling that is missing or misplaced.

US Tool Group, 2000 Progress Drive, Farmington, MO 63640, 800-222-1771, Fax: 800-886-8668, [email protected], www.ustg.net.