How Additive Manufacturing Enables Fast Modification of Molds

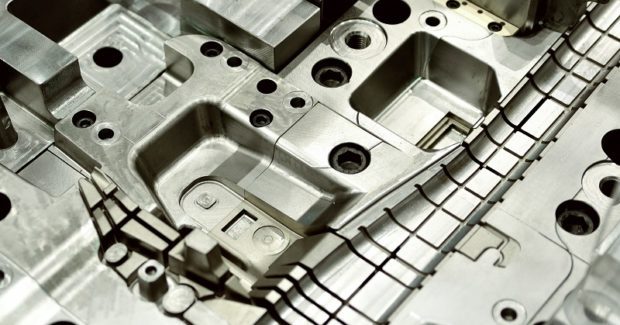

Direct metal deposition (DMD) with a coaxial powder nozzle can feed metal powder into a laser beam onto an existing three-dimensional surface to enhance surfaces, modify shapes, and restore damaged forming, punching, and injection molding tools and dies to like-new condition.

Posted: April 17, 2017

Since the start of the 21st century, laser cladding has become established as a highly effective process for modifying and repairing injection molds and dies. Now a new additive manufacturing technique is taking laser cladding to the next level: Direct metal deposition (DMD) with a coaxial powder nozzle. In DMD, a powder nozzle coaxially feeds metal powder into the laser beam onto an existing surface. The process can be completely automated and even works with laser systems with an average output of only 300 watts. DMD can be used on three-dimensional surfaces and lends itself to a wide range of uses that include enhancing surfaces, modifying shapes, and restoring damaged forming, punching, and injection molding tools and dies to a like-new condition.

New additive manufacturing-capable laser welding systems (referred to as Additive Manufacturing 2.0 or AM 2.0) can now be equipped with a recently developed powder nozzle from O.R. Lasertechnologie GmbH (Dieburg, Germany) that permits fully automatic layer buildup. This system holds enormous potential for tool and mold making applications at small and midsized shops. In contrast to conventional laser cladding, which usually requires a welder to feed filler wire almost entirely by hand, this new DMD approach is fully automated, highly precise, and boosts productivity enormously: DMD can be up to 250 percent to 330 percent faster than manual laser cladding. It can economically enhance existing equipment, which is especially attractive as a competitive advantage for small and midsized companies.

The enormous benefits of this additive manufacturing process won over our midsized shop, a tool and mold making company in Eppertshausen, near Frankfurt, Germany. One of the challenges that we face is that of building up a structure measuring 300 mm x 20 mm x 20 mm (i.e. with a volume of 120,000 mm³) on a typical mold material (AISI H11, one of the internationally most used hot-working steels that is extremely wear resistant). In the past, structures like this were built up layer-by-layer with wire-fed laser cladding to avoid the risks of cracks, deformation, and altered metallurgical properties. The welder took between 60 hours and 80 hours to complete the task. But today, we use additive manufacturing and are able to create the same structure by applying layers that are 250 µm thick at a rate of 5,000 mm³ per hour. This means we can finish the job in only 24 hours at a laser output of only 400 watts. Time-consuming secondary finishing by EDM or milling is significantly reduced.

https://youtu.be/QeaqaFEoraY

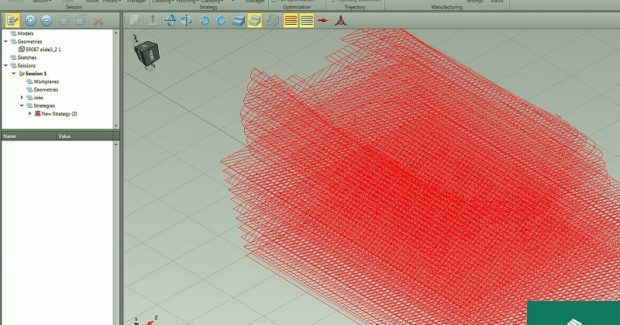

First, a CAD file that defines the addition is loaded into the powerful ORLAS Suite of CAD/CAM software from O.R. Laser. Here the addition is sliced into layers and the optimal strategy determined. Then the coordinate system is calibrated with three characteristic reference points, and the laser parameters are transmitted to the system. All of these preparations take an average of about an hour to complete. The fully automatic manufacturing process then takes place. The laser system is also flexibly controllable while the object is being formed to permit on-the-fly adjustment of the process parameters to meet changing requirements. For example, the laser intensity can be varied: beginning with fast layer build-up with a relatively high output and powder feed rate, and then reducing both toward the end of the process to create surfaces that closely approach the final contours and thus minimize the required finishing work.

The result is a crack-free, high quality structure that is optimally fused with the base material and has a hardness of 45 HRC to 65 HRC. Time-consuming preheating of the mold insert is no longer needed. The base material is affected much less than before, greatly reducing the risk of cracks and material undercut that conventional repair methods often cause. The mold insert is ready for reuse after just a short time. Laser cladding is here to stay in tool and mold making. DMD has made us more productive by letting us take a different approach when molds change. We have firmly integrated it into our process and CAD/CAM landscape. Material costs are also reduced because the DMD process produces geometries that very closely approximate the final contours. Only a tiny amount of follow-up machining is then required.

The powder nozzle is available as an add-on for existing laser cladding systems that are AM 2.0-capable and can be programmed with the ORLAS Suite of CAD/CAM software. “We are convinced that this technology will deliver considerable competitive advantages, especially for small and midsized shops,” notes Markus Wolf, the head of research and development at O.R. Laser. “This innovative powder nozzle lets a conventional system be upgraded in minutes, turning it into a powerful, cost-effective additive manufacturing tool.”