SMTCL Makes Impact with New Vocational Training

Their new programs with high schools provide students with real world skills in manufacturing .

Posted: March 14, 2017

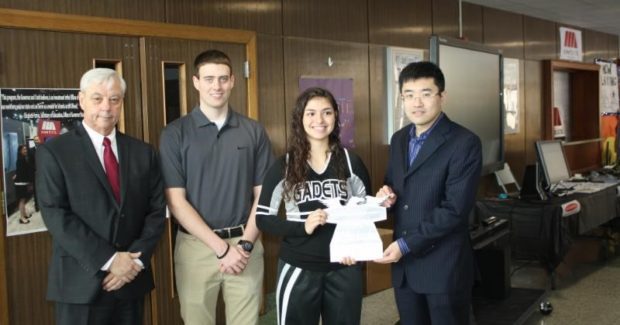

SMTCL USA Inc. (City of Industry, CA) received an award at the Digital Manufacturing Showcase event on Friday, February 10, from Galesburg High School for their part in an exciting new partnership that is bringing manufacturing training to high school students. This new program gives students an opportunity to learn CAD, CNC programming, and CNC operation. Students from six local high schools will be able to take the classes.

“Our corporation has a long history of helping young people learn manufacturing skills that can improve their lives,” said Steven Zhao, the chief executive officer of SMTCL USA as he accepted the award honoring the company’s part in providing a VMC850B vertical machining center for the students to use. Manufacturing is the nation’s biggest sector for growth in both jobs and revenue. CNC machines allow U.S. manufacturers to compete with companies throughout the world by using modern technology to make high quality components. This educational program will also help companies that need employees with skills in operating modern CNC equipment.

SMTCL distributor Pegasus Manufacturing Inc. (Galesburg, IL) has taken a lead role in developing a curriculum that teaches students skills that they need to compete in today’s world of manufacturing. “These educational programs are designed to give students the technical skills required to enter the advanced manufacturing workforce,” noted Ray Whitehead, the president of Pegasus. Although CNC training has been done in community colleges and vocational schools, this program with the high schools is one of a very few in the United States.

“High schools have been strictly focused on preparing all students for a 4-year university, when many students don’t follow that path,” added Zhao. “We are giving them another option by teaching them real-life manufacturing skills. By learning CNC machine programming and operation, students can get a good job in manufacturing immediately after high school or they can use these skills to help them if they pursue degrees in Engineering or Industrial Design.”

The award was designed by a student in the program, Selena Suarez, and manufactured in aluminum on the VMC provided by SMTCL. “Seeing this machine tool take a computer design and turn it into a 3D object that you can touch is incredible,” said Suarez, whose next project is to design a prototype for a new jeep stated.

The VMC850B VMC has the latest FANUC control that is the same control used by manufacturers such as Caterpillar, John Deere, and Ford Motor Company. By learning to program on FANUC control, students will be prepared for a job with most major manufacturers.

SMTCL is the largest machine tool manufacturer in the world producing 80,000 machine tools each year and has annual revenues of $2.9 billion. They have over 300 products, including CNC boring mills, vertical turning centers, vertical machining centers, horizontal turning centers, horizontal machining centers, gantry type machining centers, pipe threading machines and tapping centers. They also make conventional lathes, boring mills, and radial drills and have design centers in Berlin, Germany, and Shanghai, China. as well as multiple factories in Germany and China. Their Technology Center in City of Industry stocks machines, replacement parts and accessories. The company has a network of full service distributors in North America who have extensive training, parts, installation, and field service capabilities.

Pegasus Manufacturing is a leading contract manufacturer of complex machined parts and assemblies for the food processing, automotive, industrial, and mold and die industries. Their facility utilizes some of the most advanced and accurate CNC milling and CNC turning equipment available. Their quality inspection department hosts some of the most accurate test equipment to meet the most extreme demands of today’s machine industry.