Extremely Precise High Speed Dot Peen Marking

The column-mounted ec1 dot peen marking system from SIC Marking is ideal for marking small to medium sized parts, from plastics to hardened steel up to 62 HRC in various shapes and surface conditions, including flat, concave, convex, circular, raw, machined surfaces and more.

Posted: March 21, 2017

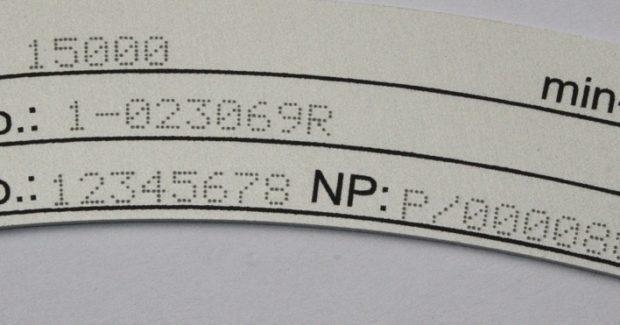

The new ec1 column-mounted dot peen marking system from SIC Marking USA (Pittsburgh, PA) achieves permanent marking of all industrial components by using dot peen technology that provides a reliable and unalterable marking directly into the material. The ec1 column-mounted machine is extremely precise, marks at high speed, and has an excellent robustness that is perfect for all types of dot peen marking. Shops can mark data such as texts, logos, 2D codes, QR codes or datamatrix codes. This new machine is ideal for marking small to medium sized parts, from plastics to hardened steel up to 62 HRC. Parts of various shapes and surface conditions can be marked, including flat, concave, convex, circular, raw, machined surfaces and more.

Thanks to its improved stability, the new design of the ec1 makes the system more comfortable to use on a tabletop, with a graduated column for easier positioning. Its new marking window is bigger (120 mm x 100 mm) and its controller is equipped with a 95 mm x 54 mm HD color screen. The ec1 controller is fully programmable thanks to a new industrial keyboard, and it features completely redesigned software for simpler handling and increased intuitiveness. The software allows the user to easily and quickly create marking programs directly from the controller using new navigation icons that facilitate switching between different menus. The main innovation is the “Edition Menu” that can be programmed in graphical or in table view (selectable at any time).

SIC Marking USA, 137 Delta Drive, Pittsburgh, PA 15238, 412-487-1165, [email protected], www.sic-marking.com.