Creating an App to Simplify CNC Operator Processes

Because the fully open OSP control from Okuma allows for complete customization, Moser Engineering was empowered to innovate an app on their own.

Posted: March 23, 2017

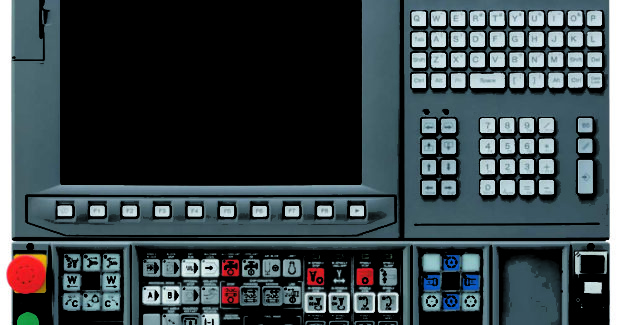

Okuma America Corporation (Charlotte, NC), a world leader in CNC machine tool manufacturing, shows how one of their users created an app to simplify processes for their operators. Their customer, Moser Engineering (Portland, IN), had operators without a lot of CNC machining experience and they needed to find a way to make the user process on their machine tools as easy as possible. Okuma distributor Gosiger (Dayton, OH) went into the control and created a GUI interface so that the Moser operators don’t even see the OSP controls or have to call up any programs at all. The app also provides safeguards so the operators can’t crash the machine tool. Check out the video below to see how this open control works for optimal machining performance:

This video demonstrates how an open architecture control enables users to customize solutions that fit their unique needs and applications. This is the first in a series of videos that show how a CNC control can be used to innovate and drive business growth in machine shops.

Okuma America Corporation, 11900 Westhall Drive, Charlotte, NC 28278, 704-588-7000, Fax: 704-588-6503, www.okuma.com/americas.