Comprehensive Turning Software with Powerful Toolpaths and Techniques

From accepting and programming any CAD file to Dynamic roughing and precision finishing, Mastercam 2017 Lathe software from CNC Software gives users a variety of techniques to turn all of their parts exactly as they need them.

Posted: March 23, 2017

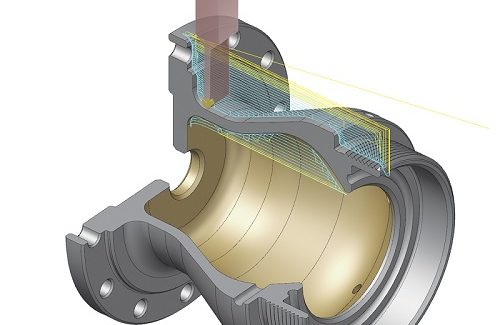

From accepting and programming any CAD file to Dynamic roughing and precision finishing, Mastercam 2017 Lathe software from CNC Software, Inc. (Tolland, CT) gives users a variety of techniques to turn all of their parts exactly as they need them. This software features a new Chip Break option, TNRC Control, Stock Model Enhancements, and so much more. The Align Solid Body function simplifies the process of aligning solid models for turning. Users can define the center of the rotation for the part and select the appropriate geometry. The software will then rotate to an isometric view where you can use the dynamic gnomon to adjust the origin. Chip Break is a new option and dialog box that has been added to the Lathe Rough and Lathe Contour Rough toolpaths to establish when chip breaks occur. This is valuable when working with stringy materials such as aluminum or plastic, and allows you to set length and time conditions, retract, and dwell options.

The TNRC Control for B-axis Turning Operations has a Tool Angle dialog box that contains new options which were previously only available for Mill-Turn operations. These options tell the software which quadrant was used to touch off the tool. If the user is creating a toolpath and the tool’s control point is not where they want it, they can use these options to swap it. Also available in Mastercam 2017 Lathe software is:

- Simplified process for selecting the tool plane, origin, and display mode in the Lathe operations.

- The new Axis Combination / Spindle Origin dialog box filters available tool planes, displaying only those planes with the correct orientation for the selected axis combination.

- Lathe Stock Model operations now allow you to manipulate the Lathe stock boundary using Mill operations.

CNC Software, Inc., 671 Old Post Road, Tolland, CT 06084, 860-875-5006, www.mastercamlathe.com, www.mastercam.com.