Third Generation Absolute Inductive Encoders Increase Safety

With improved vibration specifications, a more durable multi-turn gearbox and increased permissible axial motion of the shaft, ExI 1100 series rotary encoders from Heidenhain are ideal for automation and robotics safety-related applications up to SIL 3, Category 4 PL e.

Posted: February 28, 2017

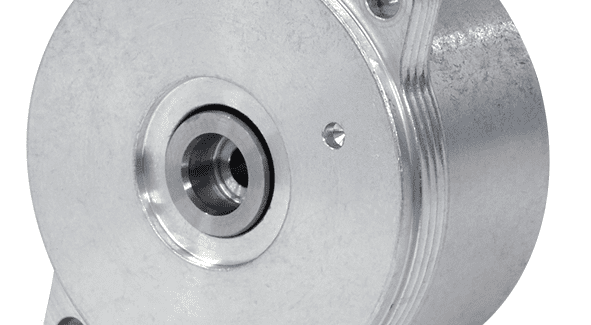

In Booth 2563, Heidenhain Corporation (Schaumburg, IL) expands their third generation of absolute inductive rotary encoders with the ExI 1100 series, providing a single encoder safety solution for many industries, such as packaging, plastics machinery, automation and robotics. These new encoders are especially suitable for safety-related applications up to SIL 3, Category 4 PL e. Both ECI 1119 and EQI 1131 encoders feature an increased single turn resolution of 19 bits, while the EQI 1131 can track 4096 (12 bits) revolutions. The ECI and EQI encoders showcase improved vibration specifications (400 m/s2 stator and 600 m/s2 rotor), as well as a more durable multi-turn gearbox, and an increased permissible axial motion of the shaft up to ±0.4 mm. These encoders also have the advantages of previous bearingless, inductive encoders which include the non-contact design, resistance to contamination, no mechanical self-heating, and reduced sensitivity to radial runout.

The ExI 1100 series joins the ExI 1300 encoders as the new generation of Heidenhain encoders that feature improved accuracy, robustness, and speed stability. The new ExI 1100 and ExI 1300 inductive rotary encoders are compatible in their mounting dimensions with the optically scanned rotary encoders with integral bearing of the ExN1100 and ExN 1300 series. The mechanical and electrical compatibility achieved this way make it possible to select the best suited rotary encoder from the Heidenhain program for the specific control requirements of the application and minimize the number of motor variants.

Heidenhain Corporation, 333 East State Parkway, Schaumburg, IL 60173, 877-565-9151, www.heidenhain.us.