Streamline the NC Validation Workflow

VERICUT 8.0 machine simulation, verification and optimization software from CGTech ties complex processes together by monitoring and evaluating many potential problems in an efficient and consolidated method that reduces the time spent in the programming and machining cycle.

Posted: February 2, 2017

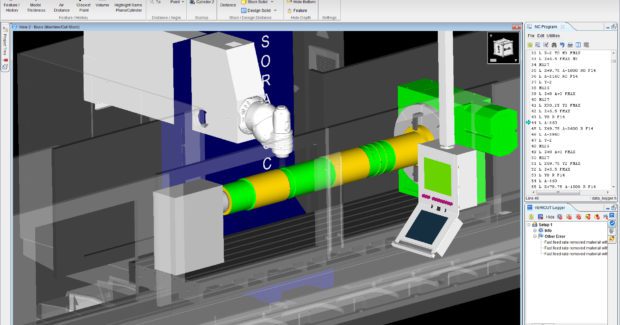

In Booth 2118, CGTech (Irvine, CA) will demonstrate tips on how VERICUT 8.0 CNC machine simulation, verification and optimization software streamlines the NC validation workflow. The software operates independently, but can also be integrated with leading CAM systems. “This release is all about optimizing user workflow to quickly access only the menu choices needed at the time,” said Gene Granata, the product manager of VERICUT. “The new Ribbon Bar helps users find the functionality they need quickly and with minimal mouse clicks.” VERICUT 8.0 features several enhancements designed to increase the ability of manufacturing engineers to analyze, optimize, and document the CNC programming and machining process. Intelligence gathered from both the cut part and the machining process is applied to achieve an even higher level of accuracy and efficiency.

CGTech is increasingly challenged to simulate more complex processes and machines, while supporting “first part, good part” production goals. VERICUT 8.0 ties complex processes together with the ability to monitor and evaluate many potential problems in an efficient and consolidated method, thereby reducing the time spent in the programming and machining cycle. The software detects collisions and near-misses between all machine tool components, such as axis slides, heads, turrets, rotary tables, spindles, tool changers, fixtures, workpieces, cutting tools, and other user-defined objects. Users can also set up ‘near-miss zones’ around components to check for close calls and detect over-travel errors. Machine movements and material replacement can even be simulated while stepping or playing backwards.

CGTech, 9000 Research Drive, Irvine, CA 92618-4214, 949-753-1050, [email protected], cgtech.com.