Quickly Restore Stainless Steel and Other Metalworking Surfaces

The ReStore Kit from Madison Chemical quickly restores stainless steel surfaces, including those marked up during equipment installation and repair. Users can clean, etch, remove surface oxides, and prepare a wide variety of metal surfaces.

Posted: February 6, 2017

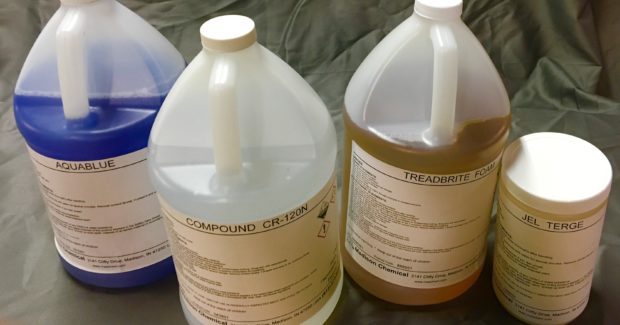

Madison Chemical Company, Inc. (Madison, IN) introduces their ReStore Kit, a combination of several of their cleaning and surface preparation products that are ideally suited for many metalworking cleaning, surface preparation and passivation applications. The multi-product kit comes in one box that contains one gallon of AquaBlue™ general purpose multi-metal surface cleaner, one gallon of TreadBrite™ Foam acidic cleaner for multi-metals including stainless steel, one gallon of CR-120N Nitric Acid cleaner for passivation of stainless steel, a two-pound container of Jel Terge powdered viscosity enhancer/gel builder, and detailed instructions. This comprehensive kit allows users to clean, etch, remove surface oxides, and prepare a wide variety of metal surfaces.

When used with the Compound CR-120N, this kit can help to start to passivate some 300 series stainless steels where desired. Ideal uses include fabricated metal surfaces, especially where L series stainless is used and post-weld clean-up is required, where an exposed metal edge has been aggravated by CO2 laser cutting, or in areas where sulphurized cutting oils and metalworking fluids have damaged stainless steel surfaces. It is ideal for field repair work, especially during or after equipment installation and commissioning, and makes an excellent add-on kit for OEM equipment because it can speed “sign off” on installs.

AquaBlue multi-metal surface cleaner is an alkaline detergent which is ideally suited for removal of dirt, oil, grease, sulphurized cutting oils or metalworking fluids, and more from a wide variety of surfaces, including stainless. It can be used as a spray, in foaming or gelling applications, as a soak, in ultrasonic tanks, and with pressure washers. TreadBrite Foam is an acidic cleaner which while it can be used on many metal substrates was developed for cleaning and removing heat tint / weld burns from stainless steel surfaces. It is ideal for cleanup of severely fouled press brakes or other fabrication equipment, including removal of all class I rouges and many class II and class III rouges. It can be used as a spray, soak, in foaming and gelling applications, or in ultrasonic cleaners.

CR-120N is a nitric acid cleaner which is well suited for passivating stainless steel surfaces. It can be used as a spray, soak, or combined with the powdered Jel Terge that is in the case box to form a “clingy” gel solution. This gel solution is extremely effective on soils and deposits in high-heat areas like class I, II and III rouges which are problematic for many cleaning agents. In gel form, two gallons of CR-120N make-down solution will clean and help start to passivate 200 sq ft of a stainless steel’s surface area. By using a gel solution option, a production group can eliminate the need for a large soak tank and still have an extended and safe dwell contact time of a solution on a parts surface.

Madison Chemical Company, Inc., 3141 Clifty Drive, Madison, IN, 63755, 812-273-6000, [email protected], www.madchem.com.