Complete 3D Analysis of Tools and Parts

By combining a transmitted light camera and laser sensor to scan, then digitize cutting tools and production parts, the Walter HELICHECK 3D non-contact CNC measuring machine from United Grinding can create 3D models of those tools and/or parts that users can save, process, analyze and measure.

Posted: February 27, 2017

United Grinding North America, Inc. (Miamisburg, OH) offers their Walter HELICHECK 3D non-contact CNC measuring machine that combines a transmitted light camera and laser sensor to scan, then digitize cutting tools and production parts. It then creates 3D models of those tools and/or parts that users can save, process, analyze and measure. The machine’s special 3D Tool Analyzer software allows users to lay vertical, horizontal and freely selectable cutting planes at any position on the 3D model. From there, the software automatically analyzes the planes and provides exact measurements of the model’s parameters such as core diameter, rake angles and spiral pitch. Because the measurements are from the 3D model, users can work offline on a separate station.

The HELICHECK 3D machine also applies Walter’s new 3D Matcher software that allows users to overlay two 3D models within a graphical user interface and perform a color-coded comparison. After the “match” of both models, the user receives an instant evaluation of the quality of the products and any deviations from the desired values.

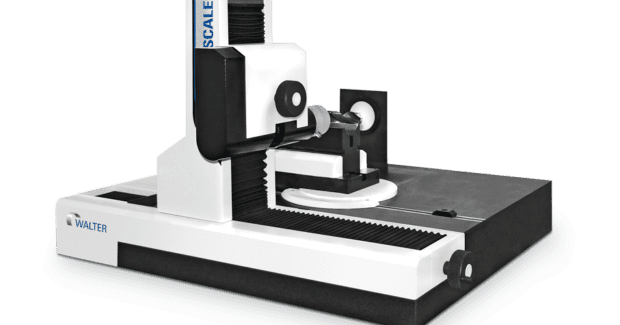

United Grinding also offers the HELISCALE measuring device from Walter that delivers precise results for re-sharpening or production of rotationally symmetrical tools. HELISCALE is easy to use and requires minimal training to check and measure a wide variety of tools, including drills, milling cutters, reamers and step tools. With the measuring device, operators can quickly and efficiently inspect tools for cutting edge wear; first and second clearance angle; point thinning angle point, radius and depth; tip angle; cross blade width; length of cut and more.

Mounted on a lower cabinet, HELISCALE features a granite base to ensure high measurement precision of larger and heavier tools up to 50 mm diameter and 300 mm long. The base plate rotates 90 deg in two directions with fixed stops to allow inspection of tools from all sides and measurement of the outer diameter as well as the end face of the tool. A cross slide enables the operator to quickly move the camera to make fine adjustments, and a rod rotary encoder enables precise angle positioning. For enhanced flexibility, the measuring device accommodates a variety of base V-Blocks. The base V-Block with hardness coating slides lengthwise and has adjustable length stops for repeatable tool positioning. Alternating and 90 deg Angular V-Blocks can also be used. The device’s optical system features a high resolution USB camera that can be manually operated or used with a motorized zoom system. It has one lense with 10 zoom steps and magnifies from 16X up to 160X with a 24 in monitor to enable measurement of rotationally symmetrical tools from 2 mm to 50 mm diameter.

https://youtu.be/BRCUG6wypvQ

United Grinding also offers their fully automated 4-axis HELICHECK PRO contact-free CNC measuring machine that sets the standard for productivity, quality and precision assurance in modern tool production. Optical measurement technology is ideal for in-process quality control of sensitive materials and small parts. The HELICHECK PRO measures standard tool diameters ranging from 1 mm to 150 mm and tool lengths up to 300 mm. A sturdy solid granite base absorbs vibration and stabilizes temperatures to maximize measuring accuracy and reliability. This machine uses three cameras to certify accuracy in rotational symmetrical tools, production parts, production equipment, indexable inserts and flat parts. Each camera is free of moving parts and safely protected from dust and extraneous light, which gives the machine the highest stability, accuracy and repeatability.

Innovative axis drives and glass scales on the linear axes deliver the highest possible positioning accuracy, short positioning times and a positioning resolution of 0.004 µm. The back light camera optics have 50X magnifying optics while the front and top light cameras have a magnifying optic range up to 200X. Powerful, intelligent Quick Check Modular (QCM) software combines a range of functions and preset program templates in a customizable format. This modular structure allows users to tailor the software to their individual requirements. Functions include QCM Order Management database-backed order data collection and QCM Measurement Technology Software for measuring tools and creating measuring programs. Technically sophisticated Easy Check software incorporates digital, fully-automatic tool measurement and interactive profile detection with a simple mouse click. Easy Check software controls the CNC axes via intuitive on-screen interactions.

An optional cutting-edge SKV rounding sensor enhances the HELICHECK’s ability to measure micro-geometries of precision tools. Edge rounding optimizes the durability and cutting performance of tools. The SKV, with its own segmented-power LED illumination and precision CNC tilt axis, determines the complete micro-geometry of a blade and all other profiles on microcomponents. It breaks the limits of standard sensors in terms of geometry measurements of very fine structures. Its CNC-controlled swivel axis delivers a position resolution of 0.001 deg and 1000X magnifying optics. The system measures edge rounding from 3 µm to 50 µm.

United Grinding North America, Inc., 510 Earl Boulevard, Miamisburg, OH 45342, 937-859-1975, Fax: 937-859-1115, [email protected], www.grinding.com.