Augmented Reality Technology: The Future is Here!

Smart technologies and augmented reality are a growing part of the future of manufacturing. Shops must embrace this growing interaction between humans and computer systems in order to remain competitive in the future. Are you ready?

Posted: February 16, 2017

The Internet of Things (IoT), or Industry 4.0, has already begun to influence manufacturers. In the future, this interaction between humans and computer systems is expected to continue to improve such that all businesses will need to embrace this change in order to be successful. As the digital networking of data, machines and humans becomes increasingly important, augmented reality (AR) is poised to give metal fabricators across the board a decisive advantage. It is already an established form of interaction between machines and humans, and eventually it will offer complete integration between the real world and a virtual one.

Augmented reality also presents a new opportunity for manufacturers to optimize working methods and procedures. The decreasing cost and increasing performance of the hardware has fostered additional research on AR technologies. This research has led to the development of new areas of application, vast improvements to the technology and the ability to impact an even wider range of processes. As a result, the AR market could grow to nearly $90 billion by 2020, according to a recent industry analysis report by Digi-Capital (San Francisco, CA).

TRYING AR ON FOR SIZE

For the user, augmented reality is far less complex than one may think. It simply requires a display which enables the user to connect the virtual world with reality. Transparent and head-mounted smart glasses are among the most popular displays currently available since they allow users to see their surroundings in addition to the created environment. These glasses come equipped with technical features such as cameras, screens, microphones and speakers to facilitate the transmission of the augmented view, as projected in the user’s field of vision, as well as enable the user to record videos, take pictures or view information such as e-mails or short text on the screen. The glasses are controlled in several ways, including buttons or a touchpad on the temple, voice or gesture control, or with a connected smartphone. Eye tracking control is also on the horizon.

Since the viewing area is still too small to augment the complete environment, smart glasses are not currently capable of presenting augmented reality the way people read about in sci-fi literature. Nevertheless, the current status of smart glasses is already a big step for the future of AR. Many companies are working to develop the technology and, even though few are currently available on the market, smart glasses have been predicted to reach 50-100 million units by 2018 and to displace smartphones as early as the end of 2019.

APPLYING AUGMENTED REALITY

Although smart glasses could be a successful consumer product, the next few years of hardware and software innovations will likely come from private enterprises that are looking to use the technology to enhance their own offerings. For example, we collaborated with hardware and software suppliers to develop AR technology for service-related use. With the demands of an industrial environment in mind, these suppliers were able to develop technologies suitable for a shop floor. The next step is implementing the technology in a production setting and to make use of the technology to deliver immediate and enhanced technical machine support. But first, the customer must be prepared to operate the smart glasses, its software, and the necessary support. Standard machine training is also required because the user must be comfortable performing functions at the machine. With the training complete and the glasses in hand, the user would then be ready to return to his or her factory with the technology.

The next time a machine had an issue, the user would connect (as usual) to our technical service team for support. Standard remote diagnostic tools would help to determine the issue and whether it might be resolved by the customer. If so, they would simply need to switch on their smart glasses and connect with the remote field service engineer using a standard WiFi connection. The service technician would then guide the customer step-by-step through the fix using the variety of enhanced communication tools provided by the smart glasses. Assuming the issue could be resolved in this manner, the AR technology would significantly reduce the time and costs associated with the fix – especially considering the technical service engineer would not have to travel to the machine for the repair. The disadvantage, of course, is that any issues that could not be resolved would still require a site visit by the field service engineer, meaning some valuable time would be lost in the process. In addition, it is important to remember that with any AR application, there will be some minor costs associated with owning the technology.

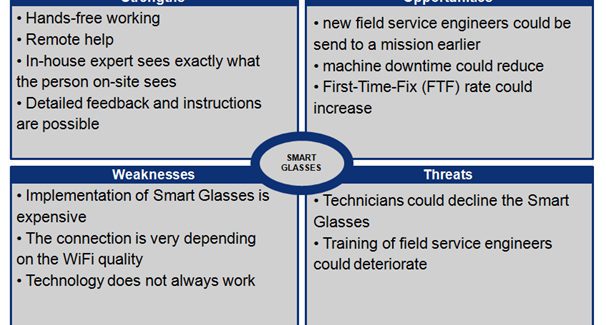

The bottom line is that smart technologies and augmented reality are a growing part of the future of manufacturing and many other businesses. Our simple example of using AR technology in sheet metal fabrication serves to demonstrate the ways technology can be applied with a bit of creativity and forward thinking. However, it also necessary to weight the strengths, weaknesses, opportunities and threats of this technology – for that matter, any new technology – before a shop decides if and when implementation makes sense for them. The technology is prepared for the future of manufacturing. Are you?