A Revolutionary Metal 3D Printing Technology Suite

Agile Metal Technology software from Sculpteo deeply analyzes design compatibility for metal AM, fixes problems, automates complex modeling procedures, finds “best fit” processes and techniques, and predicts and recommends how to optimize design elements, including lattices, supports and post-processing workflows.

Posted: February 21, 2017

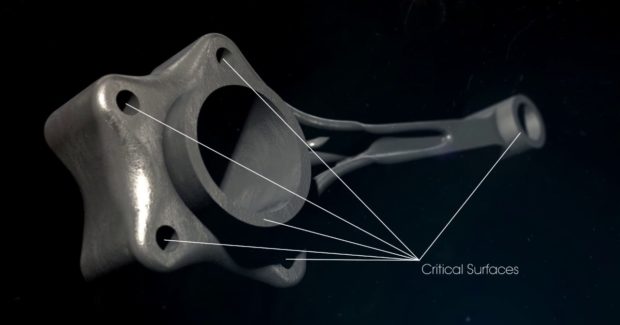

Agile Metal Technology from Sculpteo (San Francisco, CA) is a revolutionary software suite that helps designers, mechanical engineers, and manufacturers get their metal additive manufacturing projects on track. Metal 3D printing is still considered time consuming and costly, but the entire Agile Metal Technology software suite is a game changer that is dedicated to tackling every issue of metal 3D printing. It includes a total of six tools to analyze and fix problems, automate complex modeling procedures, find “best fit” processes and techniques, and offer predictions and recommendations about how to optimize design elements, including lattices, supports, and post-processing workflows.

Business Case is the first tool of the suite, a self-learning AI that evaluates whether a CAD file is optimized for metal additive manufacturing, helps evaluate appropriate materials, and delivers an approach for cost and time budget for metal AM. Business Case is a decision support and planning tool that takes basic inputs from the user and provides an evaluation of whether AM is an appropriate process for producing the part, and of the possible risks that will follow. It offers an actionable report for free. The Smart Design Optimizer tool provides a deeper analysis of the design compatibility for metal AM and assesses the best way to handle thermic constraints. Thanks to its Thermal Behavior Simulation, this tool mimics the thermal constraints that will be applied to the part during its production. It aims at providing the best way to orientate the part to reduce thermal stress and increase manufacturability. Its Design Optimizer also detects problematic features in the design, suggests modifications and evaluates the best printing orientation for the part.

The Automatic Lattice Generator tool evaluates the force that will be applied to each part of your finished object and gives structural recommendations accordingly. It helps meet cost and weight reduction goals by recommending the best structural configuration while allowing the user to choose a preferred lattice cell design.

The Interactive Support Optimizer tool analyses your design and recommends the best way to arrange the supports necessary to meet the requirement of the part (tolerance, yield assessment, thermic release). Expert users will be able to add inputs and restrictions based on the support generated by the Agile Metal Technology platform. The Post-Processor tool analyzes the post-processing features needed to finalize the part and required metrology to meet the project requirements. It evaluates how polishing, grinding, drilling, milling and threading can be applied and calculates a timeline and a budget for those. The Batch Control for Metal tool gives users virtual control over their machine so that they can create production batches exactly how they see fit and enjoy the printing parameters that they know are working for their part.

Sculpteo, 169 11th Street, San Francisco, CA 94103, 800-814-1270, www.sculpteo.com.