Wire Bending Redefined

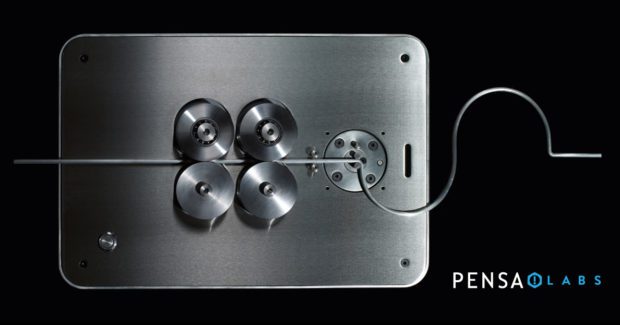

Fully customizable and affordable, the D.I.Wire PRO from Pensa Labs bridges the gap between time-consuming hand bending and expensive large-scale, mass production CNC wire bending.

Posted: January 30, 2017

Pensa Labs (Brooklyn, NY) has launched their new D.I.Wire PRO CNC wire bender that offers the kind of power, speed, and precision never thought possible from a desktop machine. Originally built as a design solution for the invention firm’s prototyping needs, this next generation wire bender has a patented bend mechanism that delivers smooth, tight radius curves: from fine orthodontic retainer wire to 3/16 in stainless steel parts applicable to jets, cars, home appliances, furniture, robotics and more. “Customers told us that they wanted to be able to perform smooth, 180 deg bends in a wider variety of materials and diameters,” said Marco Perry, the co-founder of Pensa Labs. “This machine satisfies that need and provides professional-level precision and accuracy in the process.”

https://youtu.be/y5FsqM1oM_g

D.I.Wire PRO bends wire diameters ranging from 0.028 in to 0.1875 in stainless steel (and more) up to 180 deg, making it a versatile tool for rapid prototyping and short-run production. Fully customizable but affordable, the D.I.Wire PRO bridges the gap between time-consuming hand bending and expensive large-scale, mass production CNC wire bending. “Now, shops don’t have to stop and setup a full-fledged production machine to bend out a few parts,” added Perry. “This machine really opens up a world of new possibilities for fab shops, especially when combining it with other digital fabrication equipment.”

The D.I.Wire PRO machine measures 16.25 in x 11.25 in x 13 in (41cm x 29 cm x 33 cm). Its software allows for direct control from a machine level up via a GUI or G-code, including custom calibrations and compensation controls. The SVG file interpreter allows a shop to adjust the scale and resolution of their bends or tweak their shape using an interactive interface. Connect it to a computer with a USB, load the wire, and bend the desired shape in under a minute.

Pensa Labs, 20 Jay Street, Brooklyn, NY 11201, 718-855-5354, www.pensalabs.com.