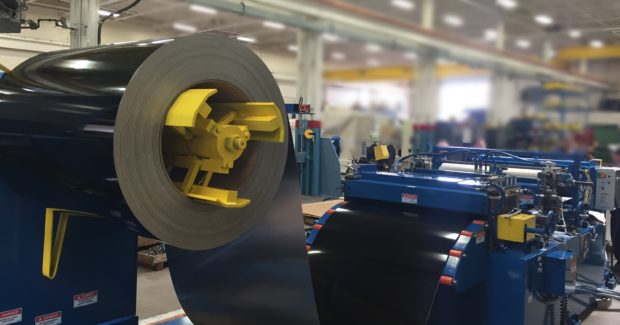

RC Trailers Installs CTL Line with Film Applicator

The 54 in wide line from COE Press Equipment can process 40,000 psi aluminum coil from 0.030 in to 0.040 in thick.

Posted: January 17, 2017

COE Press Equipment (Sterling Heights, MI) recently announced that they have designed, shipped and installed a CTLMaster™ cut-to-length line with a film applicator station at RC Trailers (Middlebury, IN), a manufacturer of cargo and aluminum trailers. The 54 in wide line is comprised of a standard motorized coil reel and servo roll feed with a special film applicator station option, as well as a special pull-thru straightener with non-marking chrome finish rolls, and electro-mechanical shear and hydraulic scissor lift table.

“RC Trailers produces a wide variety of trailer styles requiring blanks in many different sizes,” noted Steve Donnay, the director of sales and marketing at COE. “By having this new blanking line in-house, they can better control their operations and reduce inventory and processing costs. This can bring them significant ROI and quality improvement.”

The line is designed to process 40,000 psi aluminum coil from 0.030 in to 0.040 in thick, and is capable of producing blanks in length from 57 in to 102 in, and 24 in to 49 in wide. In addition to the equipment, COE also provided installation, start-up and training to RC Trailers. The CTLMaster line is built from standard coil processing equipment integrated with shear and stacking solutions, providing a reliable cut-to-length line at a value price, with numerous equipment options.

www.rctrailers.com, www.coepress.com