Power for Large Oil and Gas Part Production

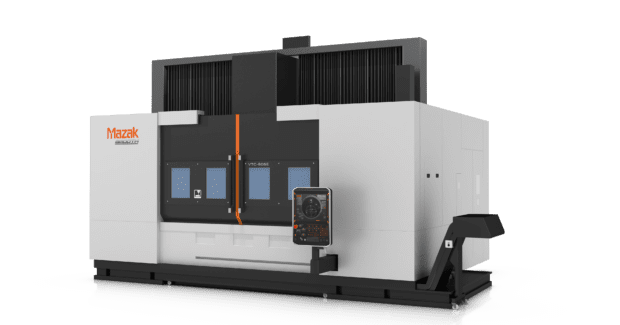

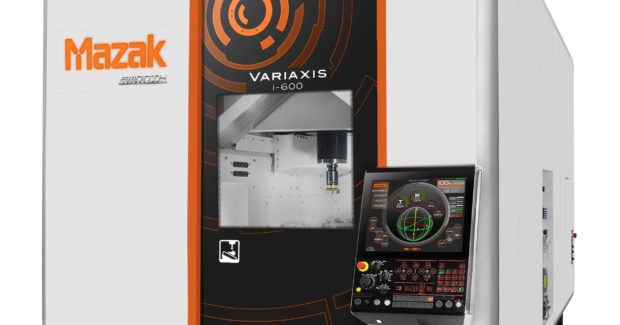

The VTC-805E Vertical Traveling Column Machining Center and VARIAXIS i-600 full simultaneous 5-axis Multi-Tasking high speed machine from Mazak bring high versatility and productivity to the production of parts used in oil and gas applications.

Posted: January 27, 2017

Made in Kentucky, the new VTC-805E Vertical Traveling Column Machining Center from Mazak Corporation (Florence, KY) brings high versatility and productivity to the production of long, heavy parts used in oil and gas applications. The VTC-805E features an increased Y-axis stroke, long bed/table size, spindle speed and torque along with its new SmoothG CNC control. It has an 82.7 in x 32.3 in (2,100 mm x 820 mm) fixed table and moving column design, along with a 69.3 in X-axis and 28.3 in Z-axis. For those manufacturers that need as much Y-axis travel as possible, the machine provides an extended Y-axis travel of 32 in as a cost-effective alternative to a bridge-style machine.

With an optional center partition, it is possible to transform the VTC-805E table into two separate work areas to process parts on one side, while operators load/unload parts on the other for an overall reduction in cycle times. A special turret-style magazine accommodates 40 tools for longer periods of uninterrupted production as well as for more part-processing versatility. The VTC-805E is equipped with a powerful 30 hp, CAT 50 taper, 6,000 rpm spindle that easily tackles a wide variety of materials including titanium, aluminum, steel and cast iron. And for even more power and speed, an optional 40 hp, CAT 50 taper, 10,000 rpm spindle is available.

The new MAZATROL SmoothG CNC makes it easy to generate programs for off-centerline machining as well as angled drilling, milling and tapping operations. Several innovative programming, performance and monitoring functions bring optimum speed and accuracy to complex part production. Advanced hardware including a tilting CNC panel and intuitive, multi-touch control screen allows for complete ease of use, while an SD card stores up to 32GB of program data.

Mazak also offers the VARIAXIS i-600 full simultaneous 5-axis Multi-Tasking high speed machine that can be equipped with an optional Multi-Pallet Pool (MPP) 500 for self-contained compact automation that is well suited for areas with limited shop floor space. This carousel-style system maximizes utilization, along with the machine’s high-performance for advanced part processing. The MPP 500 features a three-pallet rotary stocker in a two-pallet-high configuration with two sections. The system houses 12 pallets along with an external load station and an internal robot loading section. The MPP 500 is an expandable system so that shops can initially incorporate it with fewer pallets and grow the system in line with their changing production needs. It also retrofits to other existing VARIAXIS i-600 and i-700 machines (equipped with two-pallet changers) in the field.

The VARIAXIS i-600 features the MAZATROL SmoothX CNC, the fastest, most progressive control on the market and one that brings extreme productivity advantages to the most demanding of machining operations. For the VARIAXIS i-600, it ensures the shortest possible machining cycle times, especially in fine increment programs for simultaneous 5-axis operations and free-form die-mold machining. The machine can perform high-speed simultaneous 5-axis machining of a complex part’s multiple angles, as well as use an orbital machining technique to generate several different bore sizes. To reduce workpiece interference and further increase machining efficiency through the use of shorter tools, the VARIAXIS i-600 is outfitted with a compact spindle cartridge for a shorter machine spindle nose. A SuperFlow V8A 213 psi high pressure coolant system provides efficient chip evacuation and a 120-tool chain magazine is conveniently located at the operator’s side of the machine.

With an extremely fast tool change time, the machine’s automatic tool changer reduces chip-to-chip times down to only 3.4 seconds as it keeps the machine’s water-cooled CAT 40, 18,000 rpm, 30 hp (22 kW) spindle supplied with tools. Automatic tool changing is possible while the machine’s A-axis is in any position. The VARIAXIS i-600 accommodates workpieces up to 27.56 in (700 mm) diameter and 17.72 in (450 mm) high. Such capacity is ideal for those complex components, such as impellers, requiring ample Y-axis and Z-axis machine strokes. The machine has an extended Y-axis stroke of 35.83 in (910 mm) and X- and Z-axis strokes of 20.08 in (510 mm), which together expand the working envelope capacity. Rapid feedrates of 2,362 ipm (60 m/min) in X- and Y-axes and a 2,205 ipm (56 m/min) rate in the Z-axis allow the machine to quickly maneuver around large, complex workpieces for shorter overall cycle times.

For increased accuracy, the machine’s tilting/rotary table is supported at both ends and fitted to a highly rigid base without linear axis overhang and uses roller gear cams for the A- and C-axis drives. The A-axis provides a -120 deg to +30 deg range of movement and the C-axis rotates ±360 deg for highly efficient 5-axis machining.

Mazak Corporation, 8025 Production Drive, PO Box 970, Florence, KY 41042, 859-342-1700, Fax: 859-342-1865, www.mazakusa.com.