Flexible Automation of Gear Deburring and Chamfering

CNC gear deburring machines from Koepfer America can be configured with brushes, discs, milling tools and to match the exact required application.

Posted: January 18, 2017

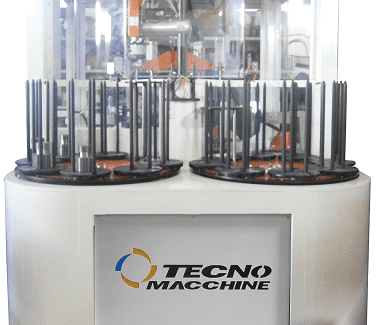

Koepfer America, LLC (South Elgin, IL) has expanded their robust line of gear manufacturing solutions by partnering with TecnoMacchine S.r.l. (San Salvo, Italy), a manufacturer of CNC deburring and chamfering machines that offers several options for flexible automation. Consequently, North American gear manufacturers will benefit from TecnoMacchine’s fit in Koepfer’s line of high-tech machine tools.

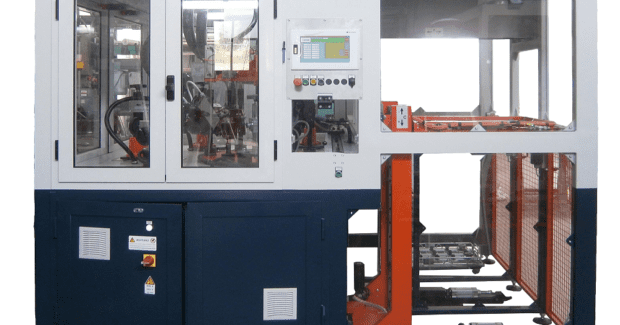

Multiple standard machine models and configurations are available, but Koepfer also configures each machine to suit a customer’s specific needs. For example, their TM 200 gear deburring machine features five work stations that can be configured with brushes, discs, milling tools, and more to achieve the exact operation required. Moreover, this model can be configured with a CNC basket-type loading and unloading system for large volume work, a flexible, stacked pallet system, or a robot system. For large gears, the TM 1000 is designed for parts up to one meter (39.4 in) diameter in the range of 12 module to 42 module (0.6 DP to 2.1 DP). This machine features tool wear compensation and four CNC work stations that can be configured as required by the application. These machines can also implement CNC tools for a full range of controllable chamfer.

Gear manufacturers will find an optimal solution from TecnoMacchine for their gear deburring and chamfering needs. Many have already: for example, their equipment is used by world class gear manufacturers, such as Koepfer and Getrag in Europe. Koepfer America is proud to exclusively represent and support these machines in North America.

www.koepferamerica.com, www.tecnomacchine.it