Efficient Bending of Large Tubes and Pipes

By end forming on flanges and optimized processing of large tubes and tubes with small diameters, large tube bending machines from Transfluid offer fast tool changes and permit narrow radii, even in CuNiFe and stainless steel pipes.

Posted: January 30, 2017

Demand for increasing process efficiency in international ship construction and offshore projects relies more than ever on time and cost saving tube bending machines used to fabricate large tube diameters. Transfluid Maschinenbau GmbH (Schmallenberg, Germany) has developed “t bend” advanced tube bending machines for high performance processing of tubes with diameters up to 325 mm. These large tube bending machines offer fast tool changes and permit narrow radii, even in CuNiFe and stainless steel pipes. End forming on flanges is a strength, as well as optimized processing of large tubes and tubes with small diameters.

“Our bending technology considerably reduces production costs while saving up to 60 percent in cycle times. This is an unbeatable benefit in the international markets,” explains Stefanie Flaeper, the managing director of Transfluid. “We offer enormous flexibility that, together with the extremely short tool change times of less than 20 minutes, permits a clear increases in tube production efficiency.”

As the trend moves toward flanges being welded to the straight tube before bending, Transfluid “t project” bending software internally links the isometrics to the corresponding CAD programs for direct processing.

The mobile tablet version “t project Draft” increases flexibility with special requirements. For example, if tube data do not come from the CAD, they can be manually entered in the software if the tubes are already present and are measured accordingly. Since this is not always done in-house, but may take place directly on the ships, the tablet version increases flexibility with software that permits isometric measurement and input of tubes. This data is then emailed directly to the shop floor to launch production while further tube geometries are still being recorded on the ship.

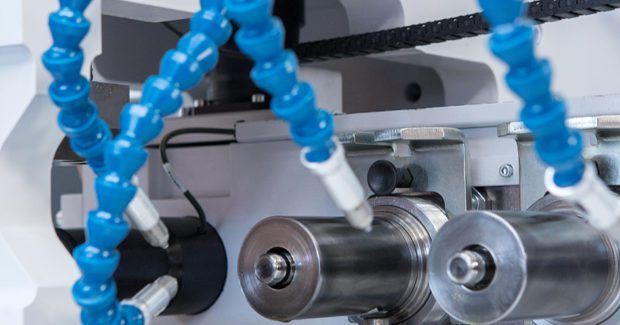

Because tubes with special end form geometry are in high demand, Transfluid offers their newly developed REB 645 axial tube forming machine with automatic tool detection. Whether for the initial production or repeated precision, the REB 645 allows tube end forming of complex geometries and extreme degrees of forming. The starting point is a barcode scanning system that reads the end forming operation data of the tube. All tools in the six forming stations of the machine have RFID sensors to ensure that the right program and the appropriate tools are available. If the automatic inspection unit detects a wrong tool, the operating panel with data memory immediately displays this information, along with identification for the correct tool to be changed. Using the convenient fork quick-connecting system for fixing and locking the bolt to secure the mount, the machine operator can directly change the tool and precisely perform the tube end forming afterwards.

The REB 645 allows the axial forming of tubes with diameters from 6 mm to 45 mm. A servomotor positions the tool sequence horizontally and vertically. Rolling stations for specific forming processes can be integrated. The machine can also be equipped with electric or hydraulic numeric drives. For extremely short cycle times, forming procedures can also be carried out gradually in transfer systems.

Transfluid Maschinenbau GmbH, Hünegräben 20-22, 57392 Schmallenberg, Germany, +49 2972 97150, www.transfluid.de, www.tube-processing-machines.com.