Direct Metal Deposition Gets Drive Shafts up to Speed on Container Ships

The labor intensive, time consuming conventional casting of alloys is becoming a thing of the past as new robot-assisted laser systems take the fabrication and repair of sliding bearings to an innovative new level in the gigantic container ships that travel across the world’s seas.

Posted: January 24, 2017

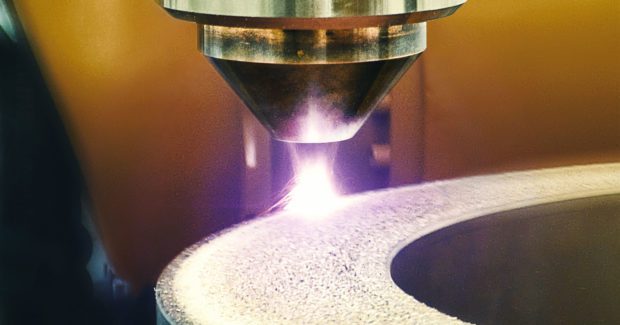

Like most of the metal 3D printing technologies, direct metal deposition (DMD) is an additive manufacturing process that uses a laser to melt metallic powder and transform the powdered metal into a solid object. However, this process is not based on a powder bed, but instead uses a powder feed nozzle to propulse the powdered metal into the laser beam. The powdered metal is then fused by the laser. Using a layer by layer strategy, the printer head (composed of the laser beam and the feed nozzle) can scan the substrate to deposit successive layers. DMD is creating a revolution in the production of sliding bearings because now it is only necessary to apply a thin layer of metal using the powder nozzle to easily, reliably and cost effectively protect the large shaft bearings used in enormous container ships from wear and tear.

New robot-assisted laser systems for DMD are taking the fabrication and repair of sliding bearings to an innovative new level in the gigantic container ships that travel across the world’s seas. These massive vessels use powerful drives in diesel engines with outputs of up to 110,000 PS and as many as 14 cylinders. The shaft that drives the propeller in these systems has a diameter of about 600 mm, weighs up to 300 tons, and rotates 84 times a minute. This shaft rests inside hydrodynamic bearings that are naturally subject to heavy wear because the shaft is in direct contact with and slides over the bearing surface. A film of lubricant reduces the inevitable friction, but it doesn’t develop fully until the oil pressure rises. Especially when engaging or disengaging the shaft, the protective film of oil is not yet or no longer sufficient to prevent direct contact between the surfaces, leaving the affected parts of the bearing subjected to considerable friction and wear that significantly reduces their life expectancy.

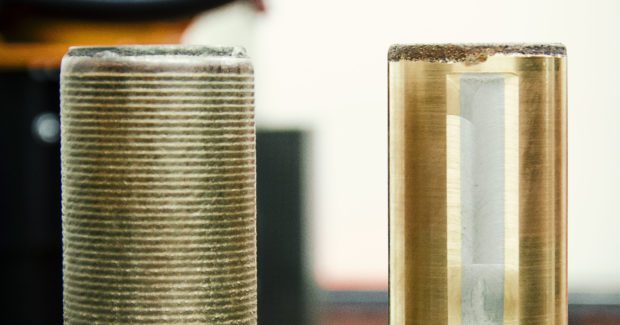

One common way to improve the performance of these bearings is to cast their halves with an unbroken surface layer of a tribological (or wear-reducing) alloy. The conventional manufacturing process used for this casting is extremely labor intensive: the metals are melted and worked at 700 deg C, then around 90 percent of the cast material is removed during a time-consuming finishing phase to obtain the desired final shape. Over the last century, this costly process has changed very little. But today, the latest generation of lasers can be used with a powder nozzle for DMD that yields considerable benefits: the metal alloy is fed in the form of a dry powder via the nozzle coaxially to the laser and melted onto the inside of the concave steel bearing shells.

The laser permits accurate partial attachment of the alloy. It is only necessary to apply the expensive alloy to about 20 percent of the surface using this technique, compared to 100 percent with the traditional casting method. Using a laser also saves time and energy because only a small amount of metal needs to be melted in each case. The new generation of additive manufacturing is especially well-suited for bearings that are in constant use, have a large diameter, and are subjected to large bearing forces and high rotational speeds. DMD can also be used to inexpensively repair defective bearing shells and restore them to a like-new condition. The ability to quickly change the alloy and apply coatings of nearly any kind of metal opens up incredible prospects for developing new products. AM enables completely new production processes that are able to flexibly accommodate customer wishes in a minimum of time.

ADMOS Gleitlager GmbH (Berlin, Germany) has more than 100 years of experience in producing cast compound hydrodynamic sliding bearings, and they are constantly engaged in improving their products and methods. Recently, they began using a robot-assisted laser system, a 6 kW fiber laser, and two high-power coating heads in the form of powder nozzles as part of a new approach to making sliding bearings. Something that was impossible with the conventional casting process is now becoming reality: namely, the use of copper-based materials such as CuSn and CuPb. One of the many advantages of this new approach is that different materials now bind more firmly to one another.

Overall, the new DMD method used by ADMOS makes it possible to completely eliminate several steps while minimizing the required finishing work afterward. Right after powering up the laser system for the first time, it became clear that this new process reduced materials costs between 50 percent and 80 percent thanks to resource-efficient application. The energy costs are also 50 percent to 70 percent less than for conventional casting of alloys. “The new laser system opens up a whole new world of possibilities for us: faster production and delivery at short notice, as well as enormous potential for slashing costs,” said Jörg Hosemann, the chief executive officer of ADMOS who was thrilled. “I expect the investment in this new laser equipment to pay for itself in no time.”