Changing the Way Things are Done with Magnets

New magnet technology is being scaled and engineered to revolutionize power from lighter weight tools for precise manipulation, positioning and cleaning, and increased safety in welding and fabrication, automation and more.

Posted: January 26, 2017

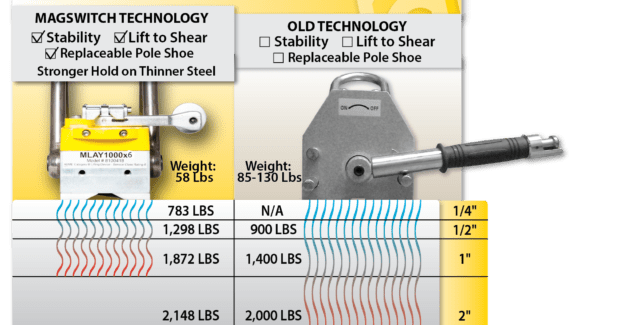

A patented and switchable magnetic technology is bringing a new paradigm to the way people perform various industrial efforts. Magswitch brings improvements over traditional uses of magnetic products, along with completely changing the way many work processes are being done, creating new uses and innovations geared towards industrial applications. Traditional, older magnetic technology is still being used every day in various industrial applications, however, there are limitations and the expectations are fairly finite in terms of the industry’s experience with traditional magnetic technologies. Older magnets are fundamentally heavier, less efficient and offer poor performance on everyday material thickness. Traditional magnetic technology is known as “deep field” in reference to the magnetic flux field being broad and circular in pattern as it travels from the “north” pole to the “south” pole of the magnet. Examples of industrial deep field magnetic products include:

- Permanent magnets are as described: a magnet that is always on, like we have holding the pictures on our refrigerators. Useful in some areas, but limited in power, maneuverability and keeping clean from steel debris ever present in manufacturing. Some uses are seen in welding, in terms of fixturing and holding an angle in order to weld pieces of steel together. In certain steel lifting scenarios, permanent magnets are used and then ‘pried’ off when not in use. They are limited to small tools and inevitably become cocooned in waste dirt and metal dust.

- Passive shunt magnets represent tools that use a permanent magnet within the tool body; the magnet can be rotated in order to make the tool become ‘on’ when the magnet is aligned properly and ‘off’ in the opposite direction when the magnetism is ‘absorbed’ by the tool body (it never fully shuts off). This is commonly seen in manual lifting and some weld fixturing tools. To absorb the magnetic field, considerable steel is needed, making them heavy. They need up to 3 inches of steel to achieve their rated safe lifting claims and the force to turn them on is considerable giving a potentially dangerous kickback when operating.

- Electromagnets use electrical power to create the magnetism. Power is needed at all times, which can become a safety concern when power is cut. Commonly used in magnetic drills, heavy steel lifting and scrap yard magnets.

These deep field magnets have many limitations. They are less versatile and limited in strength, especially on thinner metals. They can be difficult to position or keep clean, very heavy and importantly overheat if not allowed to cycle off regularly.

INVENTING A DIFFERENT WAY

Magswitch is an invention that uses powerful neodymium magnets. Two magnetic fields are employed, and when combined they create the lightest, strongest magnets on thin material that are available. To achieve a completely off state, one magnetic field is used to collapse the other, creating an efficient, lightweight system with thousands of industrial applications, from general weld lift and fabrication industries to revolutionizing automation and even catching the fantasy of DIY guys in woodworking. Generally, the technology delivers new ways to dramatically increase productivity, improve energy efficiency, increase safety, delivering cost savings and shortening time to delivery.

ACTIVE SHUNTING – SHALLOW FIELD POWER!

Magswitch uses two magnetic discs with diametrically opposed polarity within a ferromagnetic housing. One magnet is anchored in the tool body and the other is rotated in order to turn the magnet on and off. In the ‘off’ position, the top magnet is aligned so that the opposite polarity is aligned on both top and bottom magnets. This position contains and collapses the magnetic field within the housing when you turn the magnet ‘off.’ When turning the magnet ‘on,’ we turn the top disc so that the poles of each magnet are aligned (similar poles resist each other; we lock them together in alignment for a powerful solution). This action, along with the design of the housing, changes the dynamic of the magnetic flux; instead of the broad circular pattern, Magswitch condenses and contracts the flux (‘shallow field’) for a uniquely powerful output. The exponential power achieved is 130 percent to 160 percent more than the magnetic components have on their own. A small Magswitch tool can deliver surprising magnetic force that is equivalent to 500 times its own weight!

Magswitch delivers dramatically increased power from a lighter weight tool. It’s completely switchable to allow for precise manipulation, positioning and cleaning. Increased safety can be achieved in multiple industrial channels. This technology can be scaled and engineered in order to handle a variety of industrial applications, from heavy fabrication and steel handling to intricate automation systems where irregular surfaces and thin metal need to be individually manipulated. It is a green technology because little or no power is needed in order to achieve a multitude of industrial solutions. Efficiency, productivity and safety are being delivered to welding and fabrication, shipbuilding, steel service industries, steel handling and lifting, woodworking, magnetic drilling, municipalities and utilities, end-of-arm-tooling in automation, OEM integration and more.

LIFTING THE BOTTOM LINE

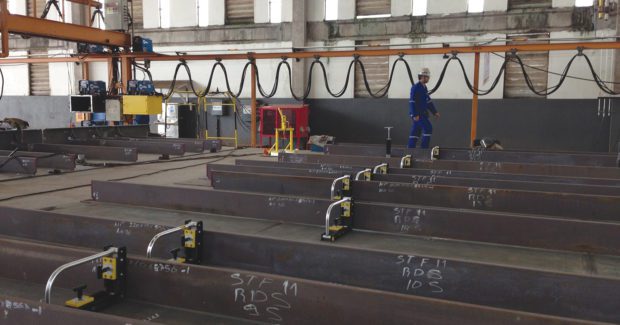

One example in productivity can be explained around Magswitch shipbuilding tools, where new systems have been developed that radically improve upon several existing shipyard fabrication processes. Large plates are fabricated in shipyards with a series of parallel angle iron called ‘stiffeners.’ Bulkheads and stiffeners are welded to base plates by first positioning and then welding them in place. The process to set them in place and tack weld them for final welding is a labor intensive, time consuming technique that entails the need to weld additional fixturing that supports the stiffener.

Once the support is in place, the operator will use heavy pins and wedges in order to get the steel plate to touch the stiffener (there is a large gap that must be closed because the plate and the stiffeners are not straight and even). Once the two touch, a welder will tack weld the joint and move down the line to the next portion of these long set-ups. After the joint is welded, the operator then needs to remove the fixture and grind the welds that held them in place – the grind marks are called ‘scars.’ It’s very common to see ‘scars’ everywhere on steel throughout a yard. ‘Scars’ mean labor, cost and time . . . a lot of time! Magswitch tools can dramatically reduce the time in this process while eliminating the need for additional fixturing and post removal and grinding. The tools eliminate the ‘scars’ and the high costs associated with the traditional way of shipyard fabrication.

The increase in productivity and time saved with this new system is three to four times faster, which extrapolates into tremendous efficiency. In other words, the return on investment of a Magswitch system can achieve rapid payback.