CAD/CAM Software for Complex Aerospace Applications

Version 4.0 Release 3 CAD/CAM software from Tebis can shorten cycle times by roughly 30 percent in laser cutting and trimming through improved NC point distribution in more compact programs.

Posted: January 25, 2017

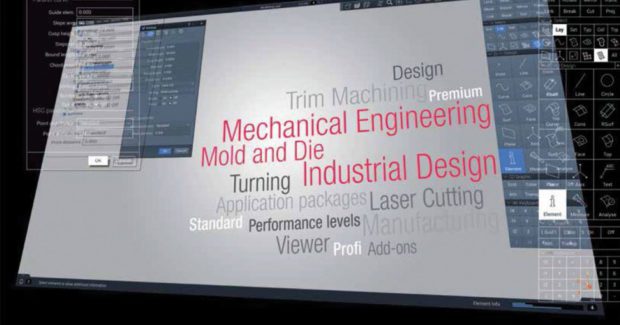

In Booth 737 during AeroDef 2017, Tebis America Inc. (Troy, MI), a leading software company specializing in CAD/CAM systems for design and manufacturing that service the tool, die, mold, aerospace and defense manufacturing industries, will feature their newest version 4.0 Release 3 software. The highlights of the new launch include toolbars and menu panels that can be easily docked to the edge of the application window; software interface that allows a user to learn to operate it more quickly and easily and with less effort; and a new project dialog with the most recently used files is displayed immediately after the program is started.

Version 4.0 Release 3 also improves the display of wire-frame models and isolines. Further, the software focuses on a more efficient use of time by automatically breaking up assemblies and complex files into multiple individual files. Another time-savings benefit is optimized reverse engineering. Release 3 provides improved algorithms that generate perfect transitions for four-edged surfaces.

In surface modeling, when generating surfaces with constant curvature, Release 3 supports symmetrical areas and provides better management of input parameters when using optimization functions.The user can shorten cycle times by roughly 30 percent in laser cutting and trimming because the improved NC point distribution results in more compact programs. The user can set axial tolerances and manually remove NC points.

To meet the demands of manufacturing industry, the company offers multiple industry-specific bundles. All with the intent to fit the size and ability of a user. These scalable levels are intended to create an exact fit for a manufacturer’s CAD/CAM/NC process chain. The Standard version is an affordable, entry solution that fits most shops. Companies that have standard 3 axis NC milling machines and utilize low end CAD/CAM products will be able to acquire the power of Tebis at similar pricing. The Pro version is ideal for mid-sized companies that are utilizing multi-axis machines and demand a higher level of automation for their operation. The Premium package delivers the complete solution package making the highest automation and highest strategies available.

Tebis America Inc., 400 E. Big Beaver Road, Troy, MI 48083, 248-524-0430, Fax: 248-524-0434, www.tebis.com.