Workcells Reformed into Value Chains

FSK 4.0 software from FFG uses mass customization, remote control and monitoring, and traceable QC by employing technologies of integrated machine-robot control, management of equipment utilization, real-time control and monitoring, as well as factory-to-market and traceable quality control.

Posted: December 28, 2016

The challenges of Industry 4.0 are shortening product time to market, increasing flexibility, and enhancing efficiency. To strategically cater to these demands, Fair Friend Group (FFG; Taipei City, Taiwan) partnered with Siemens Corporation (Elk Grove, IL) and KUKA Robotics Corporation (Shelby Township, MI) to design and build FSK 4.0 software that features mass customization, remote control and monitoring, and traceable QC by employing technologies of integrated machine-robot control, management of equipment utilization, real-time control and monitoring, as well as factory-to-market and traceable quality control.

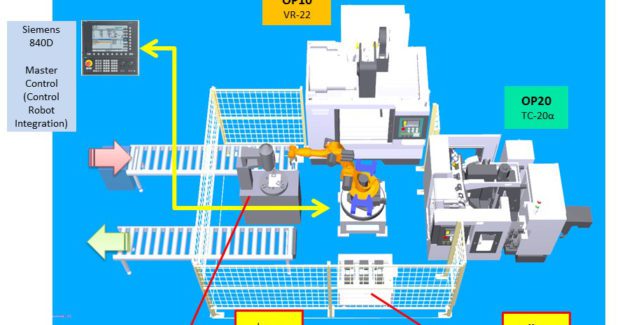

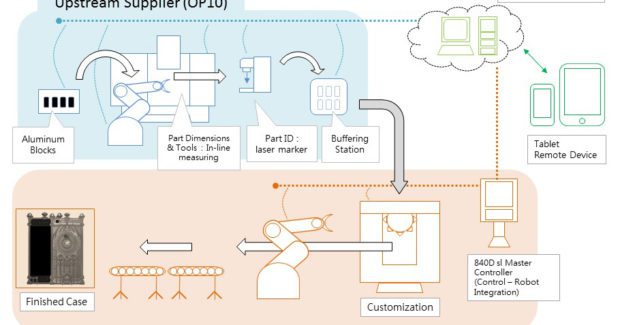

Named from the acronym of FFG, Siemens, KUKA and the Industry 4.0 theme, this cloud-based software application is ideal for Feeler machine tools with an 828D machine control running FSK 4.0 that are tended by a KUKA arm robot controlled and integrated with Siemens 840Dsl as a master controller for the whole equipment level. Apart from machinery hardware, an MES system and website (clouding) are also part of the platform architecture, a unique and one of a kind level-crossing structure that extends control beyond the workshop and into supply chain production execution, resources management and sharing. With FSK 4.0, one machine serves as the customization maker and the other as an upstream supplier, reformed into an enhanced production value chain that is capable of:

- Mass customization; highly flexible production

- Remote ordering/monitoring

- Quality traceability

- Controller-robot integrated control

- Inline inspection

- Real-time monitoring

- Machine utilization management

- Cyber-physical results simulation

In this value chain, the maker and its supplier(s) respond to market demands at the same time, eliminating delay and missing/flaw information through back-and-forth communications. At the dawn of new generation of smart manufacturing, FSK 4.0 reveals a gateway into the developing Industry 4.0 and an approach to practicing it.

Fair Friend Group, No.186 Yongji Road, Xinyi District, Taipei City 110, Taiwan (ROC), 886-2-2763-9696, Fax: 886-2-2768-0639, www.ffg-tw.com.