Welding Automation & Robotics

Take a closer look at some of the newest advances in data management, systems integration and automation, robotics and more that can help make your welding operations more productive and profitable.

Posted: December 29, 2016

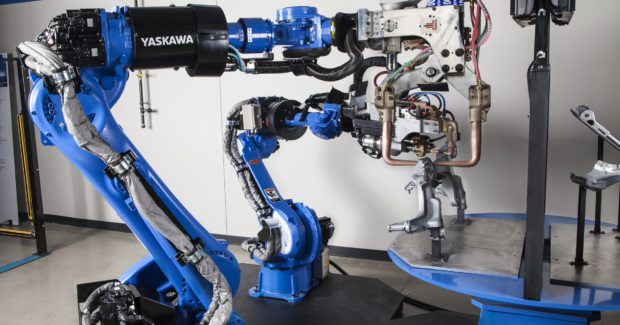

Compact Robots for Spot Welding

MS-series robots from Yasakawa Motoman are more compact than traditional spot robots for higher robot density in a workcell or around a car body, with arms that are up to 30 percent faster than traditional size spot welding robots.

Link Online Data Management of Cutting and Welding Systems

CutCloud and WeldCloud from ESAB provide a wealth of analytical tools and customizable dashboards for shops that want to use them as stand-alone software.

Advanced Robotic Welding Solutions

The ClassMate Robotic Trainer from Lincoln Electric provides complete robotic welding training, and H-Frame Weld Cell and Positioners from Easom can integrate up to four robots into a weld cell.

Simulate Welding of Larger and More Complex Components

Ideal for aerospace, automotive, shipbuilding, plant engineering and machine construction, Simufact Welding 6 from MSC Software quickly simulates longer welding seams and multiple welding points for arc welding, spot welding, brazing and stress relief, electron beam welding and laser beam welding.

Augmented Reality Delivers Real-Time Welding Feedback During Training

Ideal for training on common joint types, including pipe, in all positions, AugmentedArc from Miller Electric simulates multi-process MIG, TIG, flux-cored and stick welding by blending real-world applications with computer-generated images.

Virtual Reality Unites Manufacturing Teams

Genesis uses 3DG technology from Mechdyne to make technical recommendations, applications direction and programming requirements during virtual reviews with customers before they build a robotic automation system.

Highly Efficient Robotic Arc Welding

Hollow Wrist robots from KUKA use a single smart control system to efficiently manage the robot, motion, sequence, process and safety control for maximum energy efficiency at minimum cost.

Highly Automated Custom Welded Tubing

OMCO uses an automated 200 ft long mill to efficiently manufacture highly processed, standard-shaped tubes or custom profiles to fit applications needing non-standard welded tubes.

Maximize Gas Cylinder Economy by Changing Switching Ranges in the Field

The 547 Series High Pressure Switchover from CONCOA can fully deplete gas cylinders while accommodating applications that require continuous delivery of gas with varying high and low outlet pressures.

Compact Robot for Arc Welding and Machine Tending

The IRB 1660ID from ABB Robotics features a stronger, more rigid upper arm for heavier weld torches and improved wire feeding control near the arc to guarantee high volume production.