Unlock Hidden Real-Time Shop Floor Data for Continuous Improvement

Advanced MV2 MES software from Paper-Less optimizes production operations through unique electronic shop packets, deep integration with production workflows, browser-based user interface, multi-language support and open ERP integration.

Posted: December 20, 2016

Paper-Less, LLC (Waukesha, WI) offers their MV2 digital production operations management software that is based on manufacturing execution system (MES) technology and features new Key Performance Indicators (KPI). The MV2 KPIs offer the innovative ability to show key manufacturing performance metrics at a glance that are viewable across multiple types of mobile and computing devices. “The MV2 KPIs provide manufacturing executives and managers with sophisticated, yet easy-to-use shop floor management information that is essential to achieving important business and production goals,” explained Mike LeRoy, the president of Paper-Less. “The new MV2 KPIs help manufacturers leverage the treasure trove of real-time data that is hidden inside existing business or manufacturing systems for continuous improvement.”

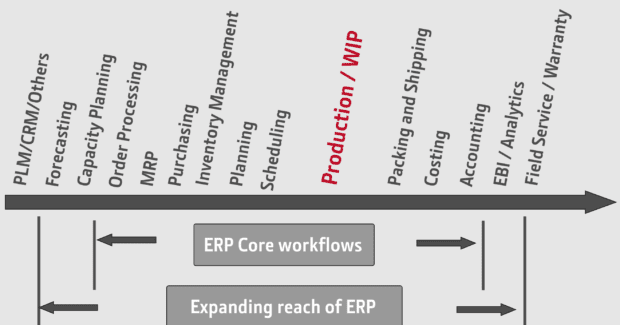

The MV2 advanced MES software optimizes production operations management by increasing efficiency while reducing paper. Unlike other MES solutions, MV2 offers unique electronic shop packets, deep integration with production workflows, browser-based user interface, multi-language support and open ERP integration. Plant managers, engineers and others gain visibility into shop floor processes, including scheduling, production and labor reporting, material tracking, quality testing and Kanban status. Real-time alerts provide problem notifications and enable manage by exception. Historical information may be analyzed for fine-tuning production operations. The new MV2 KPIs offer manufacturing executives immediate insight into the following key performance indicators about production operations:

- Downtime

- Job Efficiency

- On-time Manufacturing

- OEE

- OEE Performance

- OEE Quality

- OEE Availability

- Quality Defect Codes

“Too many manufacturers still run their production operations using spreadsheets,” noted Lorenzo Veronesi, author of IDC Marketscape: Worldwide Discrete Manufacturing Execution 2016 Vendor Assessment. “They need an MES to be the catalyst of change in an information deluge. These new MV2 KPIs offer an important next step for manufacturing managers and executives to have immediate, actionable insight about critical operating processes that are available to them wherever and however they may need to access the information.”

Paper-Less, LLC, N17W24222 Riverwood Drive, Waukesha, WI 53188, 262-354-3220, Fax: 262-567-6588, www.paperlessllc.com.