Real-Time Human-to-Machine Collaboration

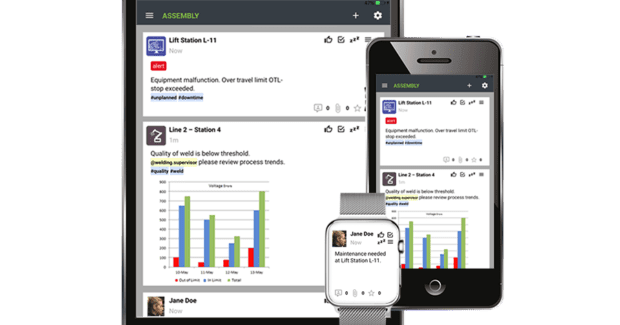

SQUEAKS is a mobile-first IoT industrial messaging app from IGear that facilitates quicker, better decision-making and closed-loop collaboration with machines as part of the conversation.

Posted: December 27, 2016

The density of robots and self-aware industrial control systems on the manufacturing floor continues to climb. According to the International Federation of Robots, “there were approximately 1.6 million operational industrial robots worldwide at the end of 2015. Getting machines and robots to be ‘team players’ and communicate effectively with their human manufacturing floor stewards is essential as the demand for industrial robots has accelerated considerably due to the ongoing trend toward automation and the continued innovative technical improvements in industrial robots.”

SQUEAKS from IGear Online, LLC (Louisville, KY) is a mobile-first Internet of Things (IoT) industrial messaging app that facilitates quicker, better decision-making, and closed-loop collaboration with machines as part of the conversation. It integrates messaging across machines and personnel and enables algorithms, rules and analysis to be applied across multiple data environments to formulate insights and prescriptive actions. This messaging keeps front-line workers and management in the know on events driven by both simple conditional alerts and complex event triggers. It enables workers to respond quickly to broaden the understanding of an event root cause, and validate ownership and closure, with timestamps. For example, the innovative SQUEAKS messaging platform can enable machines – ranging from next-generation stamping presses to innovative robotic systems – to communicate in real-time by “squeaking” with human supervisors that wear Apple watches. Using this messaging platform, the high-tech robots and machines can squeak:

- When raw material, such as welding wire, is running low or out.

- When help is needed, i.e. requests for engineering and maintenance support.

- To relay real-time performance information such as: strokes per minute, die height, tonnage, production target and pieces produced;

- To communicate operation modes: running, idle, faulted.

- In instances of other critical alerts, such as die change, e-stops, and robot collisions.

SQUEAKS runs simultaneously across equipment to provide a single pane of glass view for optimal visibility and control across the virtual manufacturing floor. “We believe the true power of IoT messaging comes from a combination of generating insightful data from industrial equipment and its ability to share this data among selected individuals, via mobile technology, to ensure clarity, ownership, accountability, and interaction,” said Don Korfhage, the president and chief executive officer of IGear. “The result is increased productivity of both machines and people.” When people and machines communicate as one and in real-time, shops benefit from:

- Improved uptime and overall equipment effectiveness.

- Six-Sigma product quality resulting in less scrap and rework.

- Lower operating costs (personnel, material management and flow, floor space utilization).

- Continuous improvement and heightened workforce engagement.

“The Internet of Things has the potential to usher in a new wave of innovation and reinvention of manufacturing as we know it,” added Korfhage. “But it’s also creating a data explosion, with some 20 billion connected devices expected by 2020. In today’s era of smart factories and connected manufacturing, SQUEAKS gives shops the means to rise above the ‘data deluge’ to improve collaboration for greater responsiveness. By making sense of business data quickly, manufacturers can understand opportunities and threats that must be addressed to support growth and profitability. This messaging platform supports improved communication and a laser focus on what’s really critical on the factory floor, for improved business outcomes and competitive advantage.”

IGear Online, LLC, 8016 Vinecrest Avenue, Louisville, KY 40222, 502-423-0999, www.squeaks.io.