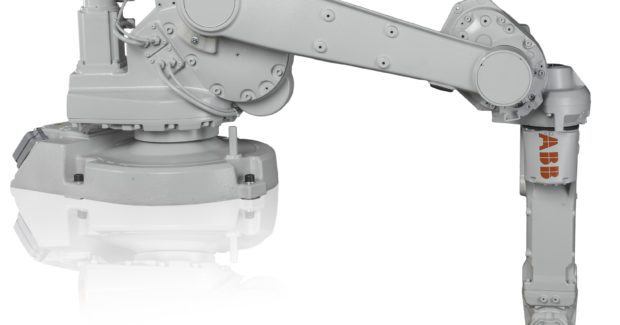

Compact Robot for Arc Welding and Machine Tending

The IRB 1660ID from ABB Robotics features a stronger, more rigid upper arm for heavier weld torches and improved wire feeding control near the arc to guarantee high volume production.

Posted: December 22, 2016

ABB Robotics North America (Auburn Hills, MI) has introduced their IRB 1660ID, their latest compact robot for arc welding and machine tending applications. The most versatile robot in the mid-size class, the IRB 1660ID’s Integrated DressPack design makes it easier to program and simulate predictable cable movements than standard robots with externally routed cables. The Integrated DressPack allows the robot to move at maximum acceleration and speed, enabling fast and reliable movements ideal for machine tending applications. The risk of collision in confined spaces is also eliminated, and the combined 1,390 deg working range of axes 4, 5 and 6 provides outstanding agility inside CNC machines.

The decreased cable wear and damage that also results reduce maintenance costs by 50 percent, and the compact footprint allows for more efficient robot cell layouts, saving valuable space on the factory floor. “Our aim from the beginning was to deliver a robot that offers superior and consistent quality in arc welding, as well as a fast, agile and reliable machine tending solution,” explains Dr. Hui Zhang, the head of global product management at ABB Robotics. “This robot will allow shops to increase productivity, deliver better work piece quality and reduce cycle times.”

To meet the growing demand for superior and even quality in arc welding applications, the IRB 1660ID features a stronger, more rigid upper arm, with a reach of 1.55 m and a payload of 6 kg. It is able to accommodate heavier weld torches and provides improved wire feeding control near the arc to guarantee high volume production. This, combined with TrueMove™ technology and the new motion process “Accuracy mode,” provides 0.05 mm path repeatability for excellent welding results. “As a direct result of close collaboration with our customers, the IRB 1660ID also includes a new generation of accurate, efficient and reliable motors,” adds Zhang. “We spent a great deal of engineering effort making the robot as rigid as possible to better protect it, and to equip it for the confined spaces in which it is designed to operate.”

ABB Robotics North America, 1250 Brown Road, Auburn Hills, MI 48326-1507, 248-391-9000, www.abb.com/robotics.