Advanced Robotic Welding Solutions

The ClassMate Robotic Trainer from Lincoln Electric provides complete robotic welding training, and H-Frame Weld Cell and Positioners from Easom can integrate up to four robots into a weld cell.

Posted: December 21, 2016

Employers in every region are demanding that welding educators deliver prospective employees prepared to work with advanced technologies like robotic welding and programming. The new ClassMate™ Robotic Trainer from The Lincoln Electric Company (Cleveland, OH) provides welding educators with a complete advanced manufacturing solution for robotic welding training, demonstration and recruiting at every level, including community and technical colleges, trade schools and workforce development programs. The ClassMate robotic cell features a compact robotic arm from FANUC® Robotics, the most popular robot manufacturer in the United States. The classroom-ready system comes with everything needed to get started, including instructor training, curriculum, a fully functional welding power source, integrated fume control and safety equipment, and a large expandable surface that easily sets up in seconds.

Designed to fit through a standard doorway, the ClassMate cell allows instructors to teach robotic programming concepts in the classroom using common 120V input power and quickly move to the lab for hands-on welding practice. Using available WeldPRO® software, students can perform offline programming and then test their skills on the manufacturing-ready robotic cell. An optional patent-pending robotic 3-in-1 welding fixture allows students to practice a number of industry-standard weld joint configurations. The cell comes with more than a dozen complete project curricula designed to encourage active inquiry, higher-level thinking and easy integration into advanced manufacturing education programs. Each lesson provides learning activities, step-by-step instructions and discussion questions. Purchasers also enjoy access to Lincoln Electric’s Train-the-Trainer Program, including curriculum and safety materials, as well as a basic robotic training course for up to three instructors.

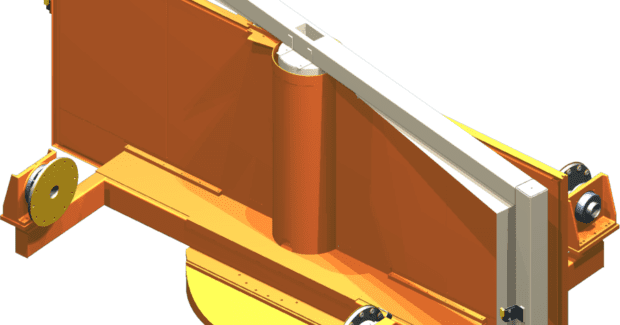

Lincoln Electric also offers their new H-Frame Weld Cell and Positioners from Easom Automation Systems Inc. (a Lincoln Electric company; Madison Heights, MI) that can integrate up to four FANUC robots into the weld cell and combine with a Lincoln Electric power supply, depending on the user’s needs. The floor-mounted H-Frame weld cell features two-piece, modular construction, including the robot base assembly, for easy installation. Complete perimeter guarding includes safety light screens and solid panels. The final main axis sweep has wedge-lock positioning. The H-Frame weld cell is ideal for use in a high production capacity environment and/or high precision applications. The robot mounting configuration allows for a small footprint, the quick-change tool frame allows for multiple tool change-outs, and the modular build allows for a low-effort redeployment of multiple or future products.

Options include integration of single, dual, triple or quad robots to applications; a fume extraction hood; an operator convenience package, including a fan, light and 110 volts alternating current (VAC); overhead bridge mounting, with or without servo slides, that can convert into two to four robots; high-speed, roll-up safety doors; and optional controls package with Allen Bradley/Siemens programmable-controller and HMI. Available high capacity H-Frame positioners are rated at 1,000 kg (2,200 lb) per side, with a maximum load offset of 90 mm (5.5 in) and two available axis heights: 740 mm (29.5 in) and 900 mm (35.4 in) as standard. The increased weight capacity permits multiple parts fixtures on the same frame. The positioners’ vertical-tool-exchange axis is supported by a large diameter, high capacity, anti-friction turntable bearing, with motion servo motor or robot auxiliary axis control. A hollow-bore floating tail stock allows easy fixture installation and quick changeovers, providing simple utility routing to the fixture.

The Lincoln Electric Company, 22801 Saint Clair Avenue, Cleveland, OH 44117-1199, 888-355-3212, www.Lincolnelectric.Com.