Unparalleled Productivity in Sheet Metal Bending

TRUMPF features the TruBend Series 5000 that comes equipped with a new On-Demand Servo Drive with 4-cylinder drive technology.

Posted: November 5, 2016

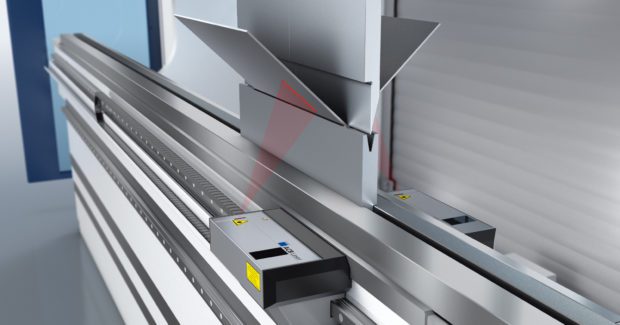

In Booth C-35041, TRUMPF Inc. (Farmington, CT), a manufacturer of fabricating machinery and industrial lasers for flexible sheet metal processing, will display their new TruBend Series 5000 bending machine with high axis speeds and acceleration rates combined with innovative operating aids that lead to unparalleled productivity. This universal machine comes equipped with a new On-Demand Servo Drive with 4-cylinder drive technology. The TruBend Series 5000 features two innovative angle measuring systems: Automatically Controlled Bending (ACB) takes measurements through sensors integrated into the upper tool, while the new ACB Laser system measures the bending angle through a contactless optical process, and is therefore compatible with any tooling.

When bending short sides, reflective surfaces, or when multi-point measurement is required, the established ACB is the obvious solution. The ACB Laser system is especially useful when processing acute and open angles, as well as thick sheet metal. This system projects a laser line onto the sheet and measures the angle with a camera for maximum precision. The entire bending process is facilitated by the new Touchpoint TruBend control concept, an intuitive interface that features realistic 3D visualization and a multi-touch screen that responds to the operator’s touch even when work gloves are worn. Support consoles capable of handling loads up to 440 lb are available with a choice of plastic, brush or roller supports. For particularly heavy and large parts, a bending aid is also available and provides assistance when bending angles up to 30 deg. When faced with differing tool heights or Z bends, an additional CNC axis automatically sets the bending support to the correct height.

TRUMPF Inc., Farmington Industrial Park, 111 Hyde Road, Farmington, CT 06032, 860-255-6000, www.us.trumpf.com.