Purge Monitor Reads Extremely Low Oxygen Levels Required for Stainless and Titanium Pipe Welding

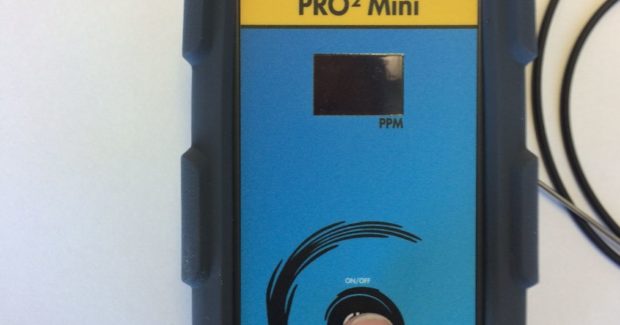

The PRO2 MINI purge monitor from Intercon provides provides quick, easy, accurate readings down to 0.005 percent (5 ppm).

Posted: November 8, 2016

In Booth N-5005, Intercon Enterprises, Inc. (Blaine, WA), a manufacturer and worldwide wholesale distributor of specialized welding, industrial and electrical goods, will introduce the PRO2 MINI, a new purge monitor in its INTERPURGE Pipe Weld Purging Systems and Accessories line. Many monitors read down to an oxygen level of 0.1 percent (1,000 ppm) and some to 0.01 percent (100 ppm), but the PRO2 MINI reads accurately down to 0.005 percent (5 ppm). An article published in the Journal of the Arkansas Academy of Science showed an oxygen level as little as 31.6 ppm led to a failure of stainless welds under fluorescent and Maglite scan. According to the manufacturer, the PRO2 provides quick, easy, accurate reading of the low oxygen levels required for stainless and titanium pipe welding.

Intercon Enterprises, Inc., 1125 Fir Avenue, Blaine, WA 98230-9702, 604-946-6066, www.intercon1978.com.