Heavyweight Modular Drive Welding System

The Heavyweight MDS from BUG-O Systems lifts upward of 180 lb in the vertical Z-axis direction without the need of additional gearboxes or other load sharing devices.

Posted: November 7, 2016

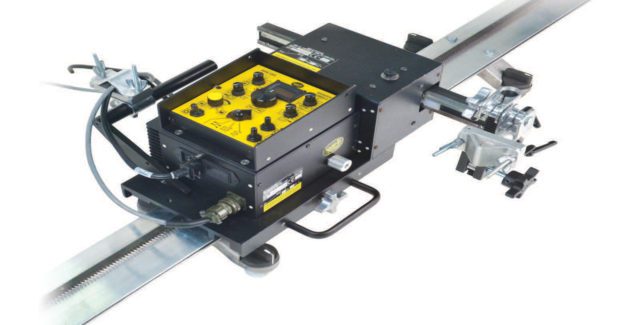

In Booth N-4329, BUG-O Systems (Canonsburg, PA), a manufacturer of portable automation products for the cutting and welding industry, will feature the Heavyweight Modular Drive System (MDS), an operational system that’s identical in appearance to the original MDS system, but works worth the strength of two to three drives combined. The machine lifts upward of 180 lb in the vertical Z-axis direction without the need of additional gearboxes or other load sharing devices. To add to the simplicity of using the MDS system, the new Heavyweight MDS will use all of the same control panels, gear-racks, weavers and accessories as the original MDS. The only difference between the original and the heavyweight is the size of the drive case and a slightly longer carriage.

Still using the same clutch, mounting arrangement and general assembly, a veteran user of the product won’t even notice a change and can operate on the same level between either an original or heavy weight system. Due to the increased payload capacity, a user can still use the same aluminum rail (ARR-1080) but is required to utilize a thicker section of gear rack to be able to handle the larger loads. To date, the original MDS system has only been able to carry (with a factor of safety) 60 lb in a true vertical position. Thanks to improvements in the motor, motor control and onboard power plant, the Heavyweight MDS can now carry weights in excess of 135 lb in the vertical positon, which gives users the ability to not only weld, but to bring everything along with the tractor to make a faster and more complete weld. Other rugged improvements for the new machine include a larger, more robust pinion as well as a larger diameter motor driveshaft to carry larger loads.

The introduction of the Heavyweight MDS is especially beneficial to industries such as shipbuilding, because it allows users in this industry to further up deposition rates and complete larger, longer welds faster to save money on long-term contract completion. Users can now have one complete, traveling welding platform which does not require a welder or welder helper to tend a welding cart, wires, etc. while a machine runs down a line. It’s all connected via carriages and trailers and will tail the unit to hasten the welding process.

Also on display will be the new KBUG-1200-BAT, a battery-operated version of the popular KBUG-1200. Built-in features include programmable seam and stick welding, digital meter, gear driven (not belts) and wheels that exceed a 450 deg rating, but now with the freedom of no cord. The power comes from an 18 V battery that’s proven to exceed the work time of two shifts. The KBUG-1200 carries the global TUV rating and will be available in a 240 V model for international markets.

Also on display will be the PCC-1 Pipe Coupon Cutting Machine, an ideal solution for welding schools and training facilities. This budget friendly machine is available at a fraction of the cost of a standard saddle and elbow cutter. The PCC-1 is used for cutting pipe to a desired length or for beveling the edge of a pipe for weld prep. The machine features a self-centering speed chuck that is capable of gripping 0 to 8 in OD pipe and 3 in to 11 in ID pipe. A racking group supports a plasma or oxy-fuel torch which can be set up for square or beveled cuts up to 12 in L. The variable speed control on the PCC-1 can be adjusted from 1 rpm to 6 rpm. A rotary ground is included on the plasma version, and a quick action manifold is supplied on the oxy-fuel version. The PCC-1 is available in both 110 V and 240 V models.

Also on display will be the new Piper-Plus welding system, which is now available with an integrated Inclinometer and the Weld Revolution SpinArc® Torch. This new pipe welding system provides the ability to make automatic, pre-programmed changes to any and all welding parameters as determined by the position of the tractor as it travels around the pipe. The newest options can be included together in the system or the system can be equipped with only the Inclinometer for use with a standard welding gun. The built-in Inclinometer provides real-world angle position data as the tractor travels. With this information, the system can be programmed to modify any of the welding parameters at any angle desired. Individual segments can be created for portions as small as one degree, depending on application and pipe diameter. The segment programming also includes a smoothing function that can be set to spread out the parameter change over a prescribed sector. It is also possible for this smoothing function to be turned off so that all parameter changes happen in the exact location requested.

The Weld Revolution SpinArc torch and controls have also been seamlessly integrated into the Piper-Plus so that the rotation speed of the Spin Arc torch can be modified via the Operator Pendant and can also be programmed to change as a function of position via the inclinometer. With these two new additions, the Piper-Plus is now a powerful tool in the high speed, vertical down application for pipe welding. With SpinArc technology, the required bevel preparation can be reduced and side wall fusion is still acceptable. This allows increased travel speeds and reduces the time needed in joint preparation.

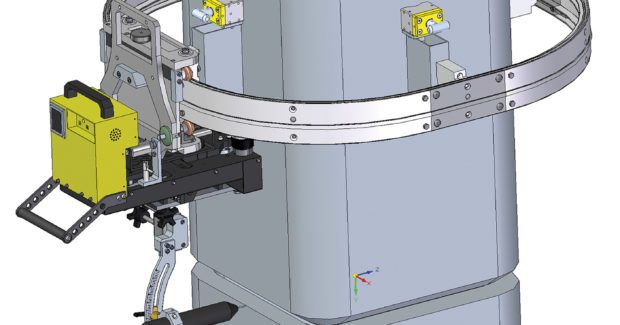

Also on display will be the KOALA welding system that welds the circumferential joint between two square box columns, standing in the vertical position. The mechanics of the system, along with the new SpinArc torch that can be used with virtually any wire feeder, enable constructers to weld the joints faster and with better quality. This torch spins the wire at the point of contact to provide better penetration, wetting action, and deposition rates. This will enable the joint profile to be reconfigured to reduce the total bevel required, thus reducing the amount of welding required. The KOALA provides a motion control system for consistent welding speed along the flats and around the small radius corners of structural steel box columns. The entire machine is supported by a specially designed square Bug-O Ring rail. The rings include special alignment tools to provide the operators with an easy way to quickly install the ring in perfect position relative to the joint to be welded.

The unique drive train of the KOALA utilizes magnetic rollers driving directly on the work piece. The torch support floats independently to maintain constant distance from the work. As the drive system moves the torch around the corners at a constant speed, the rest of the machine whips around on the ring to keep up with the torch. According to the manufacturer, the system’s precision will enable welders to perform the welding with very little need for corrections.

BUG-O Systems, 161 Hillpointe Drive, Canonsburg, PA 15317, 412-331-1776, www.bugo.com.