Heavy Duty Metal Fabrication Solutions

Hydraulic ironworkers, circular cold saws, band saws, tube and pipe notcher/grinders, manual measuring systems and programmable feed and stop systems from Scotchman Industries meet the most challenging metal fabrication needs.

Posted: November 4, 2016

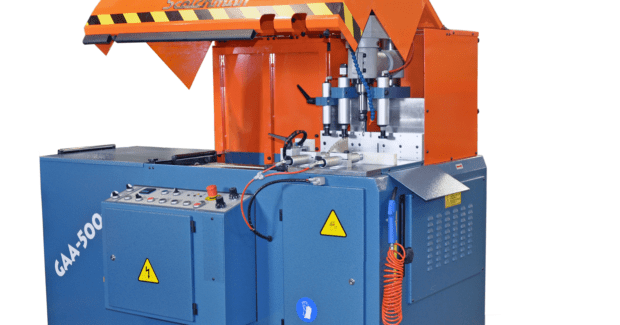

In Booth C-24047, Scotchman Industries® (Philip, SD), a producer of metal fabricating equipment, accessories and custom tools, will present their line of metal fabricating solutions, including hydraulic ironworkers, circular cold saws, band saws, tube and pipe notcher/grinders, manual measuring systems and programmable feed and stop systems. The company will demonstrate its automatic upcut production saw with drill and tap and CNC options. The GAA-500-90 DT20 CNC saw is the latest addition to their non-ferrous saw line. The GAA-500 90 is a large capacity upcut automatic saw for cutting non-ferrous materials at 90 deg. This saw uses a shuttle feed design with an adjustable vertical and horizontal clamp system to fit almost any profile. This upcut saw is available with a Drill Tap (DT20) option and a CNC option, giving it the ability to drill and tap holes up to 20 mm with a single spindle drill, or add multiple holes at one time by adding a multi-spindle drill.

The AngleMaster programmable measuring system, coupled with the SUP 600 NF upcut saw, creates a semi-automatic programmable sawing system that automatically rotates to any cut angle, pushes material into the saw and automatically rotates to the next desired angle. What’s more, users can store cut lists on its 17 in touchscreen control.

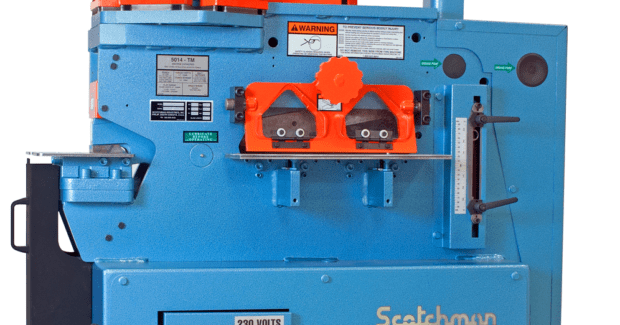

The 50514CM and the new 5014ET 50-ton ironworker models will also be on display. These ironworkers have 50 tons of pressure and can punch a 13/16 in hole in a ¾ in plate. Standard features include an angle shear, flat bar shear and rectangle notcher. The 50514CM has a single punch station and the 5014ET offers a three-station revolving turret punch station. The 5014ET comes standard with a new, improved electric stroke control for increased precision and accuracy. Fully electric stroke control also reduces the mechanical linkage which extends the machine’s life.

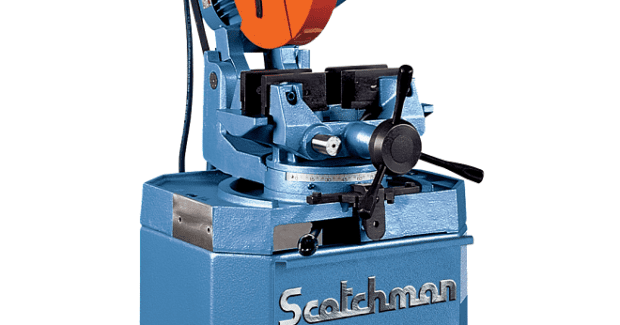

Other ironworkers on display include the fully integrated FI85 model and a dual operator DO95 model. Scotchman manufactures a full line of ironworkers ranging from 45 tons to 150 tons of pressure that are 100 percent American-made and built at the company’s South Dakota factory. Also on display will be the American-made CPO 350 Circular Cold Saw with a double clamping and self-centering vise that provides burr-free, high quality, volume parts. This saw has 135 deg mitering ability and a miter-locking device that automatically stops at 45 deg left, 90 deg straight and 45 deg right, giving it the ability to slot and notch. Additional machine features include a chip drawer, a double reduction gearbox, two-speed motor which utilizes up to a 14 in diameter blade, giving it a 4-7/8 in OD round capacity.

Scotchman Industries, Inc., 180 East Highway 14, Philip, SD 57567-0850, 800-843-8844, [email protected], www.scotchman.com.