Cut-Off Disc Cuts Faster, Cooler Through Steel and Stainless Steel

The reinforced rib on the redesigned Zip Wheel cut-off disc from Walter Surface Technologies is more rigid for consistently straighter cuts and more durability to withstand even the toughest materials.

Posted: November 8, 2016

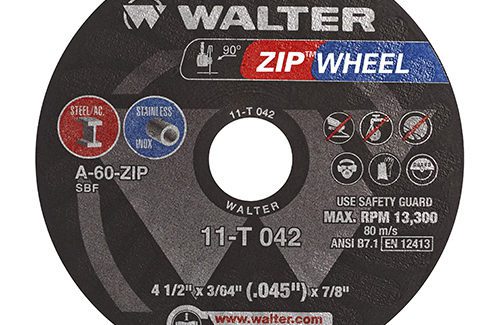

In Booth N-2704, Walter Surface Technologies (Windsor, CT), a manufacturer of surface treatment technologies, will feature the new Zip Wheel™ redesigned cut-off disc. According to the manufacturer, it lasts longer and offers more cuts per wheel than any other thin cut-off disc in the industry. The new abrasive disc offers even higher efficiency and better performance than its predecessor. Thirty years after the original product was launched in 1986, the new and improved Zip Wheel has been re-engineered from the ground up for increased performance. It is made with a proprietary grain blend so that the disc cuts faster than ever through steel and stainless steel to help reduce project times and increase productivity at job sites.

The disc is now more rigid for consistently straighter cuts. It’s constructed with a patented reinforced rib design on each side that allows for cooler cutting. What’s more, the wheel is safer for users and more durable, improving its ability to withstand even the toughest materials. The Zip Wheel is manufactured using a new and improved bond matrix, which greatly improves the life of the cutting disc. In addition, the product reduces its ecological footprint by lasting longer and reducing the amount of dust it creates, resulting in a more favorable work environment.

Walter Surface Technologies, 810 Day Hill Road, Windsor, CT 06095-1790, 860-298-1100, www.walter.com.