Co-Moving Laser Safety Up to the Clamp Point on Press Brakes

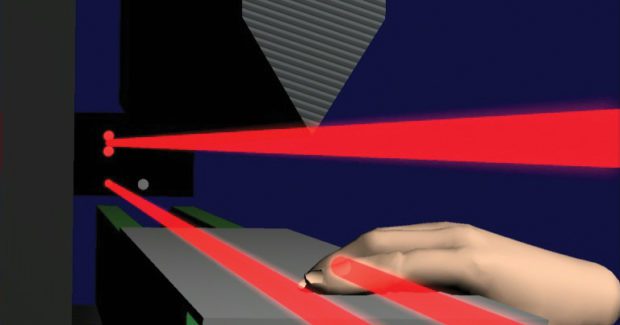

The new AKAS 3-P system from Press Brake Safety uses a 3D safety laser beam grid beneath the ram to safely operate a press brake at high speeds.

Posted: November 3, 2016

In Booth C-22092, Press Brake Safety (Zionsville, IN), the exclusive North American installer of Germany-based Fiessler AKAS® laser safety systems, will display the AKAS 3-P, the first co-moving press brake safety system that provides high speed operation up to the clamp point. By using the new AKAS 3-P press brake safety system, it is now possible to safely operate and close a press brake at high speed to the clamp point. Designed for OEMs, the new AKAS 3-P features top-level productivity while providing maximum safety. This means there will be no more loss in productivity when using this press brake safety system. The system provides full safety during regular bending and box-bending modes.

The closing movement in high speed until the clamp point is provided by this safety system during regular bending mode on modern press brakes. During the entire closing movement, the operator’s hands or fingers are protected from being squeezed between two opposed moving machine parts by the presence of the 3D safety laser beam grid located beneath the ram. The AKAS 3-P is TUV CE-type approved/cUL listed and complies with the standards of the B11.3, EN12622, Z142 and NR12.

Press Brake Safety, 1938 South 925 East, Zionsville, IN 46077, 800-901-1193, www.pressbrakesafety.com.