Thermal Drilling Replaces Welded Nuts with Stronger Formed Inserts

The thermal drilling process from Formdrill forms built-in inserts in UNC, UNF, NPT, Metric and Metric Fine threads in steel, stainless, aluminum and copper from .032 in to ½ in thicknesses with hole diameters from .059 in to 1.5 in.

Posted: October 13, 2016

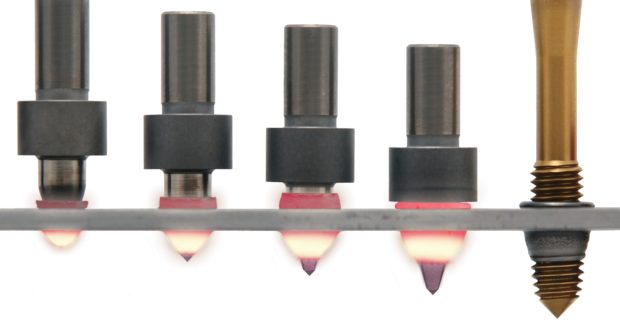

In Booth N-6814, Formdrill USA Inc. (Chicago, IL), a manufacturer of thermal drill bits, will feature the thermal drilling process to demonstrate how their tools can help form inserts out of the same part’s material. The remarkable fact about these formed inserts is that it only costs about $0.01 (one U.S. penny) to form and tap them. They are as strong, or stronger, as the equivalent welded nut of the same diameter. Formdrill will have a drill press available to demonstrate how easy it is to form these inserts. The material, which is normally cut using the conventional drilling process, is friction heated enough to soften and displace it to form a bushing that triples the material thickness. This additional wall is then used to tap and Form your Own Inserts©. These tapped bushings are used instead of welded nuts, threaded nipples and inserts. The process can be used in drill presses, CNC, or milling machines.

To appreciate the cost savings, the one cent cost per hole is to be compared to the cost of an insert or welded nut and the required labor to install or weld them. Savings can vary, but one user for many years is saving almost $2 dollars per joint since there is no need to cut the hole, clean the burrs, buy the expensive bosses and weld them. Multiplying the $2 savings per joint times the millions of holes they drill per year made it easy to cost-justify the process implementation. Another very significant benefit of the process is that parts can also be designed with lighter/thinner materials. These built-in inserts can be formed in UNC, UNF, NPT, Metric and Metric Fine threads in steel, stainless, aluminum and copper from .032 in to ½ in thicknesses. Hole diameters range from .059 in to 1.5 in.

Visitors can come by the booth ready to drill a hole with this very cost effective process. They will be amazed by the clean, no chips, operation and the feeling of pushing into butter as the metal is heated with the friction and transformed into a plastic state to Form your Own Inserts.

Formdrill USA Inc., 4118 N Nashville Avenue, Chicago, IL 60634-1429, 773-290-1040, Fax: 773-290-1041, www.formdrill-usa.com.