Snap-On Plant Awarded for Continuous Improvement

Their Milwaukee shop improved machining cycle times to increase output and win first place in Rapid Continuous Improvement.

Posted: October 20, 2016

Overcoming stiff competition from the other Snap-On facilities around the country, the Milwaukee plant of Snap-On Incorporated (Kenosha, WI) was awarded first place in the “Operations” category at their 2016 Corporate RCI (Rapid Continuous Improvement) Convention. Founded in 1920, Snap-On is now a $3.4 billion global innovator and manufacturer of hand and power tools, tool storage, diagnostics software, information and management systems, shop equipment and other solutions for vehicle dealerships and repair centers, as well as applications in aviation and aerospace, agriculture, construction, government and military, mining, natural resources, power generation and technical education.

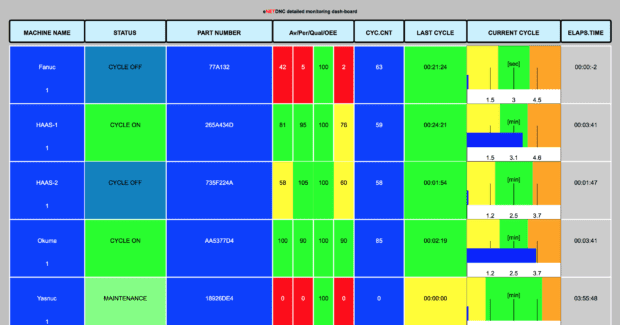

“We have been working with Port CNC, Inc. (Greenfield, WI) and using eNETDNC (Greenfield, WI) now for over ten years for program downloads,” shared Peter Zinda, the manufacturing and systems analyst for the Milwaukee plant, as he explained one of the keys for their success. “Within the last two years we installed the eNET Machine Monitoring solution on many of our machining cells. Utilizing the actual cycle time data we gathered, we were able to demonstrate how even a few second improvement in machine cycle time can significantly increase product output. This played a key role in our plant winning first place in the Operations category.”

eNETDNC is an industry leader in DNC, machine monitoring and data collection, serving manufacturers for over 25 years with resellers throughout North America. They provide free software and firmware updates and phone support without the hassle of yearly maintenance fees.

The big win by the Milwaukee plant has led to interest in eNET from additional Snap-On facilities, such as the Specialty Tools shop (City of Industry, CA) where eNETDNC and Machine Monitoring were also recently installed. “Over time we have found that eNET has been a solid performer and prompt support is just a phone call away,” added Zinda. “We especially appreciate being able to have the software customized to meet our specific needs without incurring a huge expense. Top notch all the way.”