Next Generation 3D Waterjet Pathing and Cutting Software

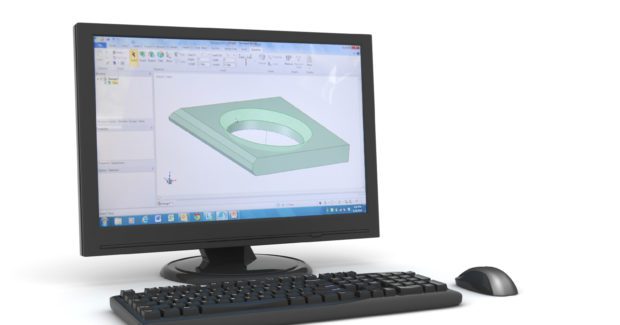

FlowXpert 2016 from Flow Corporation increases flexibility in design and pathing to improve waterjet cutting of basic and complex parts.

Posted: October 31, 2016

In Booth C-33021, Flow International Corporation (Kent, WA), a developer and manufacturer of ultra high-pressure waterjet machines for cutting applications, will display its next generation of waterjet software, FlowXpert 2016®, which is a CAD/CAM waterjet software platform for 3D pathing and cutting that allows users to work more effectively in 3D. According to the manufacturer, the 2016 release provides users greater flexibility in design and pathing which will significantly increase the benefits for basic and complex waterjet parts. The software integration was engineered in partnership with ANSYS SpaceClaim™. FlowXpert 2016 incorporates waterjet best practices, such as application tips, material cut speed knowledge, improved pathing algorithms and expanded lead in/out customization. Additionally, the program anticipates what steps are needed to provide a premier cut. Users get faster, smarter, interactive modeling integrated into a familiar interface.

The integration with the CAM Flow Sequencer module lets users design a part and path it in the same program. Modifying the geometry of a part is possible without losing the path, and the integration with Flow Sequencer will automatically update the path to accommodate the changes. FlowXpert 2016 will detect model and path errors and suggests fixes. The straightforward control means users get cutting faster. New capabilities include:

- Ability to create full 3D models and assemblies.

- Optimized pathing, including new pathing algorithms for smarter auto-pathing.

- 1-click pathing for 2D files.

- Ability to program directly from the native model without converting file types.

- Fast, versatile sheet metal processing from SpaceClaim.

- Waterjet specific geometry analysis with advanced clean up tools customized to your waterjet.

Flow International Corporation, 23500 64th Avenue South, Kent, WA 98032-2305, 253-850-3500, www.flowwaterjet.com.