Highly Accurate Pipe & Tube Cutting with Production Automation

The 3D Tube Cutting Line from HGG is fully automated pipe cutting shop in a single machine that is ideal for building cranes, trusses, stadiums, bridges, theme parks, expo centers, airport structures, shopping malls. as well as spools, manifolds, pipelines, headers, lobster backs, boilers, and nozzles.

Posted: October 13, 2016

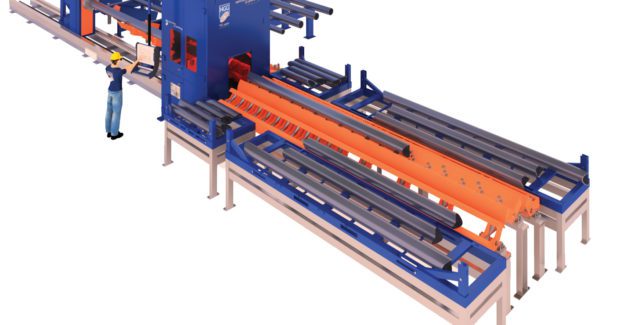

In Booth N-6125, HGG Profiling Equipment (Medina, OH) will showcase their 3D Tube Cutting Line (TCL) that combines precision tube cutting with an automated and custom designed in-feed/out-feed logistics system to increase production capacity. TCL accuracy offers fabricators a cost effective alternative to expensive laser machines, while TCL automation provides fabricators the flexibility to adapt quickly to changing production volume and tight lead times. The TCL combines a pipe and 3D tube and pipe cutting machine with an automated fabrication line with multiple out-feed stations. The end result is that fabricators have a fully automated pipe cutting shop in a single machine.

The 3D TCL is specially designed to maximize automated productivity with a minimum of operator interface. Next generation HGG 2.0 3D pipe cutting eliminates operator interference with a new “press and play” technology. The chuck-style machine design keeps the torch in a fixed position while the TCL line automatically moves material and finished parts, and at different lengths, through designated out-feed stations, from stock pipe to batches of ready-to-fit parts. The TCL reduces welding and fitting part preparation time by over 30 percent, eliminating the need for highly skilled welders. In addition, parallel-executed logistics reduce total throughput time by 32 percent. Health and safety are enhanced by the most effective fume extracting system yet, using a closed cutting cell. The TCL machine should pay for itself within a year.

For steel construction piping, the TCL is ideal for building cranes, trusses, stadiums, bridges, theme parks, expo centers, airport structures, and shopping malls. For process piping, it is ideal for spools, manifolds, pipelines, headers, lobster backs, boilers, and nozzles. HGG (Wieringerwerf, Netherlands) is a leading supplier of pipe cutting machines, robotic profile cutting lines and associated cutting equipment solutions around the world. Their subsidiary, HGG Profiling Equipment, provides comprehensive sales and service support for steel construction, piping process industries, offshore/onshore, crane building, ship building and other industries in North America, Central America and South America.

HGG Profiling Equipment BV, 3977 Rivendale Drive, Medina, OH 44256, 330-461-6855, [email protected], www.hgg-group.com.