Complexity Comes for Free

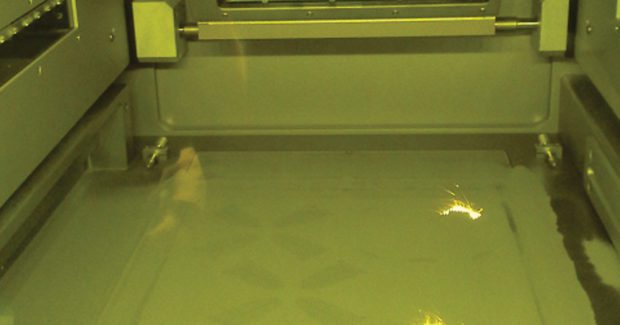

Producing metal parts in a powder bed fusion process is proving to be a game changer in the energy sector, where it generates new opportunities to produce previously impossible geometries in internal cooling channels or undercuts that are used in all sorts of heat exchangers and turbine generator systems.

Posted: October 7, 2016

“Additive manufacturing is a great game changer,” stated General Electric from a story on additive manufacturing (AM) in 2013 that has become more and more relevant today as we all experience almost exponential growth in the industry. Metal-based AM is still a young technology. However, this technology has developed in just 15 years from research and development use only to applications in the major end-use production environments. The manner of producing metal parts in a powder bed fusion process generates new opportunities to produce previously impossible geometries, including, for example, internal cooling channels or undercuts. The paradigm shift in metalworking continues as the philosophy that “complexity comes for free” (from that same General Electric story) is driving more and more companies to incorporate additive manufacturing designs into their production.

Currently, the biggest segments of metal AM use are in aerospace, medical, automotive and energy, where fields of application are already identified. Since these geometries are beyond what traditional manufacturing methods can produce, the unprecedented freedom of design flexibility opens up entirely new business opportunities. Consider the energy sector, which has benefited from new designs that reduce component weight since AM only requires material to be printed where necessary, not based on what can be or is economical to remove through subtractive manufacturing methods. For example, powder bed fusion has created a new approach in the use of conformal cooling channels built within components used in heat exchangers and turbine generator systems. This is a freedom of geometry that not only allows for improved system performance on-site, it also enables engineers to design each component for maximum performance, rather than around machining capabilities.

However, to be compatible with other conventional production methods, the biggest practical challenges for metal AM is productivity and automatization. To understand the developments that have been taking place during the last three years to improve powder bed fusion productivity, let us consider the example of a fictional turbine blade. To produce a turbine blade with conformal cooling channels out of a nickel-based alloy three years ago took two hours and 15 minutes on a medium sized, single laser machine. Today, with increased machine build envelopes and four lasers building simultaneously, the average processing time can be reduced to 35 minutes – an improvement that halves the costs per part.

In addition, powder bed fusion machines have evolved into increasingly automated machine tools that are available with a full powder recycling loop that allows for larger builds to continue autonomously and decreasing interaction with metal powders by the operator. Furthermore, it is now possible to remove and change the whole build chamber to reduce the downtime of the machines. These developments make metal AM feasible for more energy sector applications, not just those limited to only gas turbine manufacturing, but also for renewable energy applications in wind and water systems. In fact, the growing sector of renewable energy is discovering more and more possible applications that take advantage of metal AM technology on wind turbine blades or generators, among other things.

The final hurdle for metal AM, however, remains certification and quality controls. We have brought powder bed fusion machines to the market with quality control systems, automated powder handling and powder control. As the industry advances to meet strict qualifications for various applications, more advanced modules will emerge as all manufacturers of metal AM systems develop in-process quality control systems, such as laser power or melt pool monitoring. With these advances in process monitoring we will see the use of metal AM expand greatly, even allowing the potential for fast turnaround or remote printing of qualified parts – another huge benefit for the energy industry.