Precision Cutting of Very Thin Metal Without Burrs

Take a closer look at how extremely thin strips of anodized aluminum are slit and processed for electronics applications.

Posted: September 5, 2016

“Dancer regulation takes place automatically after reference positioning. Entering the operating parameters is enough; the dancers provide the desired belt tension automatically.”

The requirements of conductive materials are increasing along with the greater performance demands of the electronics industry. The strips used in motors and transformers, for example, must be light, robust, and especially precise. In order to address this demand, Alcotec Aluminum Coil Technology GmbH (Ennepetal, Germany) specializes in slit strips consisting of aluminum and copper and electrical coils consisting of anodized aluminum. They can also produce strips greater than 0.03 mm thick and 3 mm wide. Because the materials being processed are very thin and must be cut into extremely thinner strips, special production processes have been developed to ensure high quality for electronics applications.

A special high-precision slitting machine from Burghardt + Schmidt GmbH (Remchingen, Germany) is adjusted for machining of thin aluminum with small dimensions to the required accuracy. The system integrates multiple dancer regulators used for low but constant belt tension and tension-free cutting, in addition to a very exact shearing mechanism. “Due to their low weight and high temperature stability, coils consisting of anodized aluminum are now in high demand for motors, throttles, and load-lifting magnets in electronics as an alternative to copper,” explains Eckard Schmitz, the commercial general manager of Alcotec. His shop produces the slit strips required to meet the strict quality requirements of the industry. They also process thin bands consisting of copper and aluminum for transformer construction. “In both of these areas, the customer places high value on burrless cut edges and a tidy coil pattern. We must also meet very narrow width tolerances, even for narrow strips greater than 3 mm,” he adds.

The properties of the material make these demands very challenging. The aluminum panels used are only around 0.03 mm to 0.3 mm thick. This is why the slitting machine can only apply very low belt tension to ensure a unified coil pattern and limit the risk of edge bow curvature. Depending on the thickness, the yield point of the aluminum is 80 N/mm² to 280 N/mm² and the tensile strength amounts to 100 N/mm² to 300 N/mm². At the same time, tension-free cutting without wrapping must be possible so that the shears can work exactly and the strips separate at the width required with little burring.

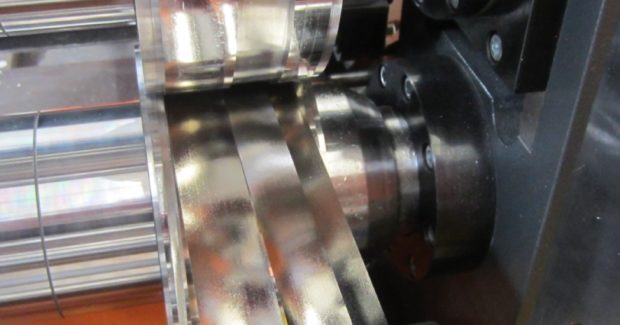

The core of the system is the shearing mechanism that can be positioned exactly and with important stability by using its precision pre-tensioned rolling bearings and clearance-free line guide. The integrated knives feature a diameter of 130 mm and may be combined with rubberized or steel ejector rings. In a single run, an operating speed greater than 100 m/min may be applied for a maximum of six cuts up to five times, depending on material strength and thickness. A gauge featuring 0.01 mm precision indicates the plunging depth of the knives during the process.

Because the widths of the cut strips differ and a tidy coil is required, various winding mechanisms are integrated to accept the strips: three for 3 mm to 30 mm, and one each for 30 mm to 100 mm and 30 mm to 200 mm. The two 4 mm to 8 mm wide edge strips are coiled and sorted out separately. These strips are separated in a controlled manner via a deflecting separator mechanism that also features rolling bearings. To enable convenient conversion of the system for diverse order requirements, the winding shafts work with coils as well as sleeves that can easily be replaced by using the quick-change clasp on the spool shaft.

The precision of the knife alone is not sufficient to deliver the required cutting quality, especially for the production of the narrow strips, so equal belt tension is adjusted to the sensitivity of the thin aluminum panel by the integrated sensitive dancer systems on both the in-feed and the out-feed. The swivel-mounted rollers provide exact, smooth running and balance out even the slightest fluctuations in tension. The first regulator on the in-feed side of the deflection roller (between the unwinding spool and the shears) enables fluid regulation of the tension between 6 N and 500 N. Additional dancers are located prior to the winding spools according to the various strip types. As such, the thin strips are only subject to 0.72 N to 72 N while the tension on the wide strips may vary be between 20 N and 600 N. Integrated encoders ensure secure position recording in both areas.

The desired belt tension may be set conveniently for the electrical motors via the system control panel. Additional control of the five dancers at the winding spools takes place automatically. “In this case, a single reference positioning run must be completed for the system,” notes Thomas Baral, the general manager at Burghardt + Schmidt. “Afterwards, it’s sufficient to specify the material parameter – such as thickness, width at in-feed, specific belt tension and strip width at the coiling spools, etc. – at the main control panel, and the dancers adjust will themselves independently.” The belt edge controller also corrects the position of the material running off the unwinding spool to create the best-possible initial conditions for cutting. The system includes an opto-electrical sensor unit that includes a measuring light barrier, an electronic control amplifier and the actual control device that is used to power and direct the electrical and mechanical linear drive for positioning.

For easy operability, a central control panel uses a Siemens touch screen to display fault messages, system speeds and related information, in addition to data entry. Additional auxiliary control panels are provided at the unwinding spool, the splitting machine shears and at three locations at the coiling spools so that important values for quality and operating safety can be adjusted everywhere as required to ensure problem-free production in spite of difficult raw production material.

“After only a few days of familiarization, the system was producing as required,” reports Volker Wandelt, the technical general manager at Alcotec. “The dancer regulator completely functions without any problems for precise winding at constant tension. The quality of the split strips being produced is very good.” The high-precision splitting machine still operates currently in single shifts, but expansion to two to three shifts is already planned.

Alcotec Aluminium Coil Technology GmbH, Pregelstrasse 20, 58256 Ennepetal, Germany, +49 (0)2333 86194-0, Fax: +49 (0)2333 86194-29, [email protected], www.alcotec.net.

Burghardt + Schmidt GmbH, Raiffeisenstrasse 24, 75196 Remchingen, Germany, +49 (0)7232 3661-0, Fax: +49 (0)7232 3661-65, [email protected], www.b-s-germany.de.