Compact Belt-Driven Spindle Direct Couples with Any Motor

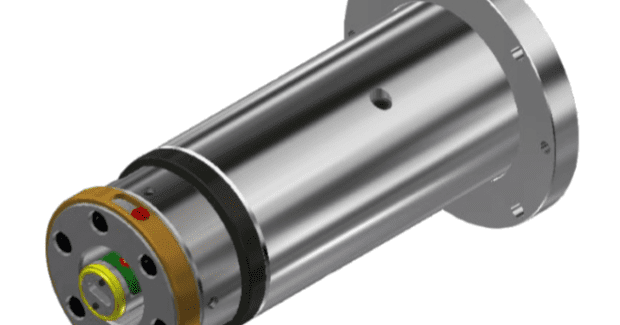

The smaller size of the highly versatile InTronix Spindle from Gilman Precision leaves a smaller footprint that reduces the overall size and weight of any given machine.

Posted: September 10, 2016

Gilman Precision (Grafton, WI) unveils their new, highly versatile InTronix Spindle that combines the affordability of a belt-driven spindle with the compact size of a motorized spindle without compromising precision. The smaller size leaves a smaller footprint as it reduces the overall size and weight of any given machine. In addition, it direct couples with any motor, allowing companies to more easily incorporate the spindle into a new build at a more affordable rate. These space-saving characteristics also benefit machines that simply have limited room for components.

“The adaptability that this new spindle offers is a game-changer for the industry,” said Doug Biggs, the vice president of sales and marketing at Gilman who believes this new product will have a huge impact on the manufacturing world. “It reduces weight and size without the added price, allowing companies to build machines with smaller footprints. We really are very excited to introduce this new product to current and future customers.”

This new spindle reaffirms the company’s place as a leader in customization for rotary motion capabilities. Gilman Precision develops customized slides and spindles for value-minded engineers with exacting needs and standards and provides expert service for virtually any manufacturer’s equipment. Serving a variety of industries and applications, these engineered solutions are advanced by a highly skilled, knowledgeable and experienced team that delivers on-time and within budget.

Gilman Precision,1230 Cheyenne Avenue, PO Box 5, Grafton, WI 53024, 800-445-6267, 262-377-2434, [email protected], www.gilmanprecision.com.