Advanced Tube Bending Technologies

The fully automatic DB 622-CNC ‘t bend’ mandrel bending machine from Transfluid performs exact bending of 22 x 2.0 mm round steel tubes, 22 x 1.5 mm stainless steel tubes, and 16 x 1.5 mm square tubes.

Posted: September 2, 2016

Transfluid® Maschinenbau GmbH (Schmallenberg, Germany) ensures bending freedom with their new, fully automatic DB 622-CNC ‘t bend’ mandrel bending machine, which has no corners or edges and is completely encased in a round, new design. “The compact design, with an integrated safety housing around the machine, allows operation with a separate safety apparatus,” explains Stefanie Flaeper, the managing director of Transfluid. The fully automatic system can be freely programmed without specific CNC knowledge by using touch panel control that allows exact bending of round steel tubes with a diameter of 22 x 2.0 mm, of stainless steel tubes with a diameter of 22 x 1.5 mm and of square tubes with a diameter of 16 x 1.5 mm. Bending angles of up to 180 deg are possible. The machine has mandrel support for the precise placement of the mandrel tip. It is also fitted with a radii changer for two changes of the processing level, which also allows processing of a tube with alternating form spanners or spanners. The maximum change height is approximately 60 mm and the radii difference between the levels is 1.5 x D.

The control system works with three individual axes for bending, turning and length positioning. Once the bending data has been entered, the bending program is automatically generated and can also be manually optimized during operation. It is also possible to split one bending process into several segments in order, for example, to achieve different speeds on one arc. The speeds of the servo axes are automatically synchronized to one another in order to minimize wear and power consumption. The system has been developed and realized as a whole in accordance with the latest technical safety regulations to ensure efficient and safe tube processing.

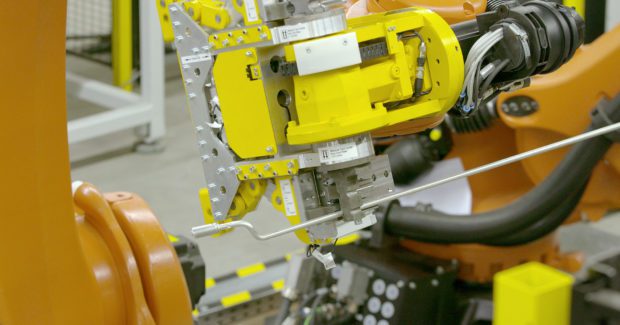

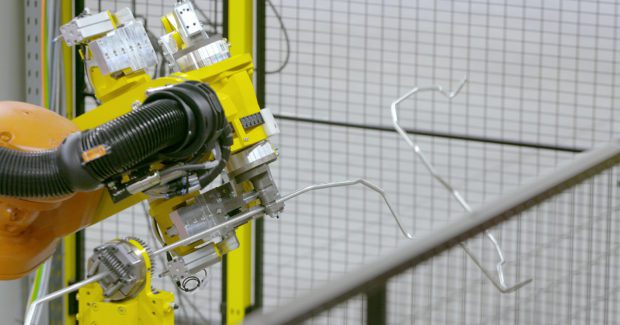

Transfluid has also developed an intelligent robot-assisted tube bending system that does not require complex programming to address the challenge of bending technology, specifically with regard to handling, in the production of lines for braking systems, air conditioning units and similar devices with a length of 1,500 mm and tiny diameters as little as 18 mm. The tube processing system uses 7-axis robot handling for material and can perform 47 bends on tube lengths up to 4,500 mm in a time of around 140 seconds. The tubing can already be shaped or fitted with flanges.

The process involves first inserting a bundle of tubes into a feeder, which are then individually orientated by symmetrical rotation according to the positioning of the flanges. Each tube is then picked up by one of the two 7-axis robots and transferred to a moveable spanning device with an appropriate high retaining system designed for longer tubing. The spanning device allows the robots to process the tubes on one or even on two sides in parallel. This speeds up the processing time for each tube to constantly less than three seconds. Both robots have drive systems and can bend right/left. Isometric data can be uploaded directly online from a CAD system so that complex programming of the robots is not necessary.

Transfluid also offers a new general combination machines for axial and rolling pipe forming. “Geometries in pipe end machining can be formed directly on the pipe, replacing usually complicated and expensive turned parts,” notes Flaeper. “No soldering or welding is needed. The pipe and its end form are virtually from a single cast.” Implementation of the combination can be specified by the user directly or based on the forming geometry. “Usually, up to 6 axial forming stages and at least one rolling unit are used. If trimming, axial and rolling forming are needed, two rolling stations may be required as well,” adds Flaeper. “We call this ‘powered axes’.”

Pipe machining may include a simple trim or deburring at the pipe end after forming. Because this process is not a demanding technical challenge, it possible to equip all axial forming machines and all combination machines with one or several single-drive axes that have a servo-electrical drive and can be used for the forming stages in each of the holders. This makes the system very compact and particularly flexible. Because the combination machines have electrical drives, all forming tools are positioned very precisely so the machines can be used much more diversely.

Transfluid also pushes the boundaries of technology in their flexible SRM automatic tube shaping machine that can be modified to create non-tool-based, CNC-controlled profiles or expand tubing (T-pieces) with the help of very simple tools. This continuous shaping machine can work with tubing chuck sizes of less than 0.5 x D to cut and shape all of these profiles in a single work process. It can produce both horizontal and vertical configurations to meet individual applications and requirements. All functions are operated servo-electrically and can also be CNC-controlled as necessary. “Multiple shaping operations of a tube end can be undertaken with the help of our pneumatically opening segment tool,” explains Flaeper. These special tools are equipped with a pneumatic system that controls and opens elements and can verify their positioning. The tools open and close to the required position during shaping to ensure that the external surfaces of the tubing remain untouched during the shaping processes so that there are no scratches or friction deposits on surfaces.

By combining this flexibility with frequently required lightweight construction concepts, especially for automotive applications, these tool systems can prepare tubing in specific wall thicknesses so that thinner tubing can be employed and wall thicknesses can be created as required for further processing in other applications. Shaping can be done before the tubing is bent to save money by eliminating expensive spanning devices for forming and reducing handling and loading. These tube bending machines also provide an automatic clamp set changer for the use of multilevel tools.

Transfluid Maschinenbau GmbH, Hünegräben 20-22, 57392 Schmallenberg, Germany, +49 2972 97150, www.transfluid.de, www.tube-processing-machines.com.